How strong is it? For this reason, they are also referred to as switching valves. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. It is suitable for automation equipment requiring high-performance hydraulic system or control of special hydraulic requirements. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact Hydraulic Valves Experts in Linquip. What are the requirements for new products? The hydraulic system with a modular hydraulic valve will be able to omit many hydraulic pipes, lower problems of hydraulic resistance, oil leakage, surrounding pollution, working vibration, large noise and often maintenance, to the great compact and simplified hydraulic system. F. Requirements for job reliability 1- The expected working life? 3- Touch rain, seawater, or other corrosive liquids? The poppet valve controls the fluid flow direction, pressure, and flow by changing the oil port size through poppet and ball spool displacement. They can also change into intermediate states to control an actuators acceleration, speed or direction. E. Cartridge Valve Please check our other article for the cartridge valve in details: Cartridge Valves By Finotek. for hydraulic valves, Nominal pressure it is the maximum working pressure allowed by long term reliable work of hydraulic control valve and this is limited by the valve intensity. Multiple Section Directional Valve (Sectional Valve, Multiple Flow Control Valve) The multiple flow control valve evolved from a screw-in manual directional valve with a valve spool that controls a set of actuators hydraulic or hydraulic motors. A: Sliding spool valve; Pic. 3- What is the quality and training level of the operator? D. Cartridge valves There are two styles of cartridge valve, cover plate type (two-way cartridge valve) and threaded types (two, three, four-way cartridge valves ). Finotek modular hydraulic valve is a widely used industry area for its advantage, like in injection modeling machines, pressing machines, hydraulic power units, and numerous equipment. Working Principle & Types (Complete Guide), What is Poppet Valve?

(Spring offset is always a type of the two-way valve). The valve is sandwiched mounted (Use like a sausage sandwiched in the middle of two pieces of bread ) between a directional control valve and subplate or manifold, fastened buy four long bolts as per hydraulic system requirements, the hydraulic system pipe system connects oil ports threaded on the manifolds or subplate. So based on these functions hydraulic valves are classified into pressure-volume or directional control valves. The reversing valves change the flow direction and they cut off or connects oil channels by the relative motion of valve core in the valve body. A 3-way directional control valve has 3 working ports called inlet, outlet and exhaust. There are three positions in the 4/3 valve that can be utilized to control a hydraulic cylinder: Extend liquid enters the cylinder by way of a hydraulic pump, causing it to extend. It is including electro-hydraulic proportional pressure valves, electro-hydraulic proportional flow control valve, electro-hydraulic proportional directional control valve, electro-hydraulic proportional multi-valve, and electro-hydraulic proportional multi-directional control valves. For example, this type of hydraulic valve would be used in control circuits for devices, such as actuators, cylinders, or motors. How To Select The Hydraulic Valves Before Ordering: There are only have the right hydraulic valves for the different working positions, no hydraulic valves that are excellent everywhere! Ports in a valves body lead into a section so that a spools situation determines which ports are open and which ones are closed. All Right Reserved. This design can be considered as an old one so it has many disadvantages like they are prone to leakage and needs more time to fix. The structure of a rotary valve is the sample, but there is a problem of spool radial force imbalance.

The oil ports would match between the holes in the manifold and oil leakage is prevented by using O-ring at each oil ports. The further standard hydraulic valve can be mounted on each side of manifold (Each manifold side is like a connection subplate), the oil flows inside the valves and manifold channels to control hydraulic force, the manifold design is being able to save mounting space in the hydraulic system and without hydraulic pipes to save the cost. However, you can change your cookie settings at any time. Special hydraulic valve is based on normal hydraulic valves for the further meet certain specific requirements and development. Home > Valves > 4 Types of Hydraulic Valves & Their Working Principles. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. Two operating ports are connected to an actuating unit. Fluid systems are typically produced for operation at a fixed range of pressures.

A. Threaded connection valves The inlet and the outlet port of the valve are produced to threaded type, to connect pipe fittings. variation range? The large-scale integrated block professional manufacturing plant has an annual output of several thousand tons. A spool is a precision fitted to a bore by the longitudinal axis of a body. A hydraulic valve properly directs the flow of a liquid medium, usually oil, through your hydraulic system. Flow control valves manage the flow by decreasing or increasing the opening at the throttling point. Scald? Vane pumps and genuine spare parts in stock;over 25,000 configurations listed in ouronline pump catalogue! These valves are used to control the flow direction of hydraulic fluid to different lines in the circuit. M. What is the first requirement? Controlling the size of the gap between the valve housing and spool, to achieve all of the oil ports on or off and the port diameters, therefore, the valve main job is to control fluid flow direction, pressure and flow control. Overall situation 1 The customer (group external or internal? The multi-section directional valve generally has a standard control block: the oil source block, also known as the main control block, has an end block typically. 5- What happened to the accident? Spring action automatically turns the spool to the center position with releasing force. The needle valve is an example of a flow control valve. 3-Peer (Competitive opponents price? The valve is most suitable for high automation requirements or customized hydraulic systems. 2022 Pneumatic and Hydraulic Company, LLC | ALL RIGHTS RESERVED, The Most Common Types of Hydraulic Valves. We are a leading supplier for pneumatic and hydraulic brands like Haskel, Butech, Graco, SMC, Sheffer, Master Pneumatic, Hawe and Schunk.

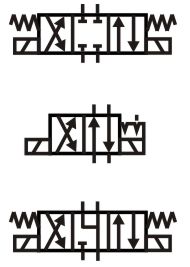

C. Cartridge valves This valve has hydraulic control feature of the element as a component screwed into a valve block or manifold, cartridge valve has extended to many sorts of function, such as directional control, pressure relief, flow control function. Direction? The three standard types of flow rate are: Some of the conventional hydraulic flow control valves are: Hydraulic pressure control valves are used to regulate the fluid pressure passing through hydraulic arrangements to keep that pressure at desired amount as restricted by the system operator. Mostly all valves have the same structure a valve body, valve spool, and components of driven valve spool movements. How high is the economic speed? They can be utilized to thoroughly check the flow level to a specific domain, redirect pressurized fluid or close a line. 2- What if a part fails, what is the threat? Neutral all liquid ports are blocked, so there is no flow of liquid. G. What are the restrictions on the appearance? @2020 - automationforum.co. B. Here at Linquip you can send inquiries to all Valves suppliers and receive quotations for free, Your email address will not be published. Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. Pneumatic Systems for Healthcare Applications. These valves usually are the sliding-spool model.  Or speed curve? According to this coding scheme, 2/2 represents a two-state valve and 4/3 a four-state valve with three positions.

Or speed curve? According to this coding scheme, 2/2 represents a two-state valve and 4/3 a four-state valve with three positions.

We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. Therefore, the use of integrated block mounting connections has become the first choice for modern hydraulic system designers. Only to understand the meaning of this sentence totally will comprehend the effects and phenomena of hydraulic valves in the actual hydraulic system or equipment. Mass flow rate we measure the mass per unit time in the units such as the kg/min or slugs/sec. Most of the integrated blocks now use cast iron, while the inner spool is made of low alloy steel.

Mass production recovery work time? See Terms of Use and Privacy Policy. Flow control valves regulate the flow this is done by adjusting the size of the bores (orifices). Because as long as a sand hole appears in a valve hole, the entire manifold is scrapped. C: Poppet valve; Pic. Does the country have a patent or a utility model? Check valves permit free flow in one direction and block flow in the opposite direction. There are many types of hydraulic valves available in the industry. Servo valve consists of a single-pole, two and 3-pole electro-hydraulic flow servo valve and electro-hydraulic pressure servo valve. The first number indicates the number of valve ports, and the second number indicates the number of valve positions that the device can achieve. The valve is widely used industrial machines and equipment. Pressure control valves switch (or control) at a certain pressure; the switching pressure may be adjusted on the valve.  If you would like to describe the hydraulic valve or hydraulic control valve in one sentence, we would like to say that: The hydraulic valve actually, is a device that can change the opening degree of liquid (Oil) flow path. As a result, in use, when the damage is caused by contamination, it is often the case that the valve block is damaged before the valve spool. A digital valve is not much sensitive to oil contamination, it is also reliable operation, high repeatable precision and good consistency for the bulk of product performance. Is there a negative load?

If you would like to describe the hydraulic valve or hydraulic control valve in one sentence, we would like to say that: The hydraulic valve actually, is a device that can change the opening degree of liquid (Oil) flow path. As a result, in use, when the damage is caused by contamination, it is often the case that the valve block is damaged before the valve spool. A digital valve is not much sensitive to oil contamination, it is also reliable operation, high repeatable precision and good consistency for the bulk of product performance. Is there a negative load?

They are used in single-acting cylinders and the third working port can block the flow of all ports.

- Parthenon Virtual Tour

- Altec Lansing Speaker Not Charging

- House Color Palette Interior

- Best Auto Racing Gloves

- Large Format Vinyl Printer Cutter

- Empress Effects Tape Delay Pedal