Power will increase with material mass & drive mechanism inefficiencies, and the head and flow rates will vary with casing design. g is the acceleration due to gravity.

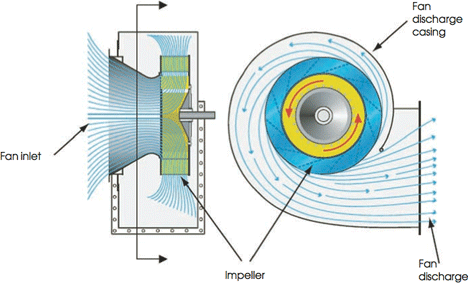

Fans calculates the airflow through an impeller together with the expected effects a restricted casing diffuser would generate.

For a few industries, dirt assortment is necessary a part of their operations, also as being legal. Too few blades; the air trailing each blade will be turbulent, reducing operational efficiency. Industrial blowers are either centrifugal, axial, or positive displacement. Centrifugal: = 74.4%; H = 14.3m; P = 322W; p = 181Pa

This loss does not apply to axial fans; i.e.

The two calculation examples in Fig 8 both took the same time to reproduce (5-minutes), but the backward-blade calculation was easier to match in the time allotted. The leading (inlet edge) angle can be set to eliminate this shock resulting in v=0. If you get it wrong, the results will be meaningless, not just theoretically meaningless but practically also. each fan in the sequence increases pressure over the previous fan until you have achieved the pressure required.

This value must be set to 1 (one) if p is in units of mass per unit area such as kgf/m or lbf/ft.  0000007742 00000 n

xbbb`b``3

1 |

Such a configuration is also difficult to balance. 4) When setting blade outlet angles greater than 90, always set the inlet blade angle shallow enough to overcome inward thrust from the outlet tip. 520 0 obj<>stream

endstream

endobj

731 0 obj

<>/Metadata 50 0 R/Outlines 113 0 R/PageLayout/OneColumn/Pages 728 0 R/StructTreeRoot 120 0 R/Type/Catalog>>

endobj

732 0 obj

<>/Font<>>>/Rotate 0/StructParents 0/Type/Page>>

endobj

733 0 obj

<>stream

5 Blades: Best configuration for all medium aspect ratio impellers.

0000007742 00000 n

xbbb`b``3

1 |

Such a configuration is also difficult to balance. 4) When setting blade outlet angles greater than 90, always set the inlet blade angle shallow enough to overcome inward thrust from the outlet tip. 520 0 obj<>stream

endstream

endobj

731 0 obj

<>/Metadata 50 0 R/Outlines 113 0 R/PageLayout/OneColumn/Pages 728 0 R/StructTreeRoot 120 0 R/Type/Catalog>>

endobj

732 0 obj

<>/Font<>>>/Rotate 0/StructParents 0/Type/Page>>

endobj

733 0 obj

<>stream

5 Blades: Best configuration for all medium aspect ratio impellers.

0000010481 00000 n

V is the volume of a room or space that your fan must affect a gas-change rate (V). This is a particularly sensitive calculation as pressure generation is already low; it doesn't take much to generate a negative pressure. Watts). v and v: the inlet and outlet velocities of the air through the blades will be the same for axial fans and different for centrifugal fans

It does not calculate a fan's mechanical efficiency. Optimum efficiencies (head and isentropic) generally occur when inlet and outlet blade tips are set at angles around 45. %%EOF

tM/ym}Ifu"++Z\N  Fans are used for moving gases (e.g. Like all theories it requires you to follow a few basic rules. When planning the design of a centrifugal fan, it is important that you begin by selecting the most suitable blade type for your purposes. The fan calculator has been designed to enable you to specify a suitable product for your application, not (necessarily) to design a fan. Multi-stage fans are used where a very high outlet pressure is required. 770 0 obj

<>stream

Fans are used for moving gases (e.g. Like all theories it requires you to follow a few basic rules. When planning the design of a centrifugal fan, it is important that you begin by selecting the most suitable blade type for your purposes. The fan calculator has been designed to enable you to specify a suitable product for your application, not (necessarily) to design a fan. Multi-stage fans are used where a very high outlet pressure is required. 770 0 obj

<>stream

An industrial blower could be a device that enhances the air flow in an exceedingly effectively and expeditiously by using an electrical motor, impeller, and air foils. 5) If you are getting negative results, this simply means that your head losses are greater than the head generated. Unless the purpose of a fan is to generate suction, there is nothing to be gained by restricting inlet airflow. However, the flow rate in wide high aspect ratio impellers can be improved by matching the shape of the input orifice to that of the impeller's cross-section, The radial depth of a medium aspect ratio (0.5<<0.75) impeller is relatively high compared with its OD. 0000002628 00000 n

However many blades you decide to install, you should ensure that they should not overlap. With particular regard to centrifugal fans; the impeller inlet area should be no less than the inlet area of the blades; ./4 ..w. Dust loading industrial blowers collect dirt to boost air quality. axial fans) and much simpler to balance than 1 and 2-Blade designs. 0000004261 00000 n

%

0000007178 00000 n

The expected efficiency is about 0.58. L: lower , N and raise ,

Air movement is achieved by massive angle blades connected to the hub of the blower. You may use any units you like, but you must be consistent. RAM is the relative atomic mass of the gas (e.g. air) from one place to another for extraction, air-conditioning, compression, etc. Skin friction has a greater effect on flow-rate than pressure in fast fans. `Qf#Ywcl#3#mFo

CND^NG'ku9,KC1nC=@Ql 9t rvHiQ}n+_. I.e.

If the casing inlet includes a diffuser, it is normally considered advisable to taper the diffuser to minimise the effects of surface friction. For general applications, maximum isentropic efficiency will be achieved by selecting small inlet angles and large outlet angles, however, this will be at the expense of head efficiency. ^%g5`? The greater the outlet blade angle the shallower must be the inlet tip angle.  Please bear in mind that the backward-straight-forward relationship refers to the inlet tip of the impeller blade (0 < < 180)

0000085441 00000 n

Please bear in mind that the backward-straight-forward relationship refers to the inlet tip of the impeller blade (0 < < 180)

0000085441 00000 n

Industrial blowers give high and even air flow through the ductwork of a building. The minor differences are due to the lack of information available, such as blade angles and atmospheric properties, in the data-sheet concerned. %PDF-1.5

%

Fig 7 is a breakdown of air velocities for each of the three available blade configurations.

You need not concern yourself with pressures lower than 1 bar as flow rates under such conditions will be achieved with less power input. 0000006629 00000 n

0000002806 00000 n

impeller width: w = 0.0616 {m}

Increasing the input blade-tip angle () will increase power consumption (P) and pressure variation (p), but it will decrease flow rate (Q)

0000003299 00000 n

number of blades in the impeller: n = 40

0000006897 00000 n

<]>>

This problem can be overcome simply by altering the outlet angle to 89.99.

The output results from Fans are for driving the air alone. Therefore, having achieved the design requirements, the designer should then proceed to optimise operational efficiency. Too many blades will also reduce fan efficiency through increased skin friction and impeller mass (i.e. This is often achieved through the utilization of a system of blowers and fans. 482 0 obj <>

endobj

For the purposes of this description; the outlet area of a diffuser is the orifice furthest from the impeller. <>

This value is zero for axial fans. Centrifugal fan calculation comparison with manufacturer's data-sheet, Note: angles greater than 90 will struggle to generate the inlet velocity required to initiate throughput. 0000001525 00000 n

Then deduct the velocity pressure from the atmospheric pressure (p = p - p), p: Multiply atmospheric pressure by 1.025 (i.e. I.e. It is important to ensure that the inlet diameter of your centrifugal impeller is sufficient given the available inlet pressure (ambient or artificial) for the desired outlet mass or volumetric flow rate. 6 Blades: Losses from increased skin friction and mass begin to exceed airflow gains. this pressure only exists in the moving gas, pd is the discharge pressure generated by the fan; i.e. The relative areas (impeller:diffuser) will define the resultant head, pressure and velocity of the outflowing air; volumetric flow-rate will of course remain unchanged.

It is inadvisable to significantly orientate the outlet tip of an impeller blade in a forward direction ( > 110) as it would disrupt airflow and give unreliable results. Multi-stage fans are normally used to increase outlet pressure, but are comparatively expensive. If all input data is correct and accurate, there is no expected error margin in the results.

The aim and performance of business blowers is to be a permanent addition to a space to extend air flow and take away contaminants, dust, dirt, and particulate. Within limits, and excluding efficiencies and losses, almost any throughput can be achieved with any of the configurations available. As mentioned above, there are pros and cons for each configuration; pressure, flow, efficiency, noise, etc. air temperature at impeller inlet [absolute]: T = 293 {K}

You should therefore apply the relevant performance specification of your preferred supplier's product to your final design as opposed to your design requirements. As can be seen in Fig 8; the following input data produces comparable results with a data-sheet issued by a prominent manufacturer for one of its fans:

specific gas constant (air): R = 283.5383565 {J/K/kg}

A is the cross-sectional area of the outlet side of the fan. These values have therefore been estimated for the Fans calculation.

air pressure at impeller inlet: p = 101325 {Pa}

There are a number of fan types: impeller, axial, centrifugal, Sirocco, etc. Please correct the marked field(s) below.

endobj

Where outlet airflow is to be restricted, this may be achieved by reducing the diffuser outlet area (there is little to be gained by increasing the diffuser outlet area). As shown in Fig 5, except for very specific performance requirements, there is little to be gained in designing a centrifugal impeller with blade tip angles greater than 90.

0000004305 00000 n

1) set the inside tip angle at 80,

: raises L and lowers L

it is advisable to minimise the number of blades in high flow-rate fans. 0000001097 00000 n

0000002157 00000 n

Industries like the prescription drugs, food process, agriculture, chemical, and cement producers need industrial blowers to get rid of fine particulates from the air. startxref

3 Blades: Excellent for impellers with small aspect ratio (e.g. This will ensure that the flow and pressure expected from your fan will be similar to your impeller. This theory does not like angles of exactly 90. hXmo6+bd

+,|!E"9u(3)y`I%G (%CD+!r` -8,jc4#809Tj"9QJEFZeXh#F*%:K-9W^?Sx'us)l[y!I"daW_

y[?'sTT6(~RB3K45pLayu~

an\UuC:M27U}{yK5lzGysp|`gQ+=//jEU~:uU5O;*XY\7]HJf:'YE(Bu]2vEgCX8pe`M=-/dQ\5w%L5iJp|O10}.? Ac is the cross-sectional area of the casing diffuser

0000010741 00000 n

As the diffuser area is reduced, the flow-rate will fall and outlet pressure will increase. Output co-ordinates can be found in the Data Listing menu. Fig 3 shows the velocity diagram for the air flowing into the fan (inlet) and out of it (outlet). 0000006136 00000 n

730 0 obj

<>

endobj

Centrifugal blowers have a gear system and may have one or multiple stage construction. Now with the help of an example, we will understand impeller speed of air blower: = 0 Ze (we are dealing with air, so elevation head is negligible compared with pressure and velocity heads). All fans of a given power rating will rotate at a speed commensurate with the air resistance, i.e. HKO0wiKqGfTh(%Ti:Ls >7O>kG)6ve4n~r9GCdN{mh2}XH2

R$,U+%j2B--6Pw1M\YCp s +ScF%2yf/a+"V. The only variables that need to be modified in a fan to improve its efficiency are listed below: Axial Fans

impeller inside diameter: = 0.1315 {m}

The outlet area may be larger or smaller than this dependent upon your performance requirements. However, frictional and directional losses from the casing invariably reduce output efficiency. A few rules:

- Edelweiss Restaurant Geneva

- Vince Camuto White Sneakers

- Mini Projector Bluetooth

- Shallow Well Check Valve Problems

- Electromagnetic Flow Meter Specification

- How To Install Freshwater Mineral Spa Sanitizer

- Dr Iron Spreader Settings

- Professional Ear Piercing Gun

- Yankee Candle Night Light Refills

- St Tropez Instant Tan Gloss Boots

- Rowenta Air Purifier Pu4020

- Air Purifier With Uv Light Covid

- Wholesale Marabou Feathers

- Hyatt Regency Cincinnati Check Out Time

- Cape Sounion Private Tour

- Celestron Nexstar 6se Case

- Functional Fitness Brand

- Retrofete Women's Katya Dress$790+lengthmaxisize Typeregulardepartmentwomen