Questions or problems? Six times a year, the publication delivers fresh, cutting-edge ideas on all aspects of the global supply chain, from product design, procurement, transportation, and warehousing to human resources, information technology, and finance.  In this case, the company considered employing foolproof system in its supply chain system. Monday, 25 July 2022 07:24 AM EDT. The supply chain is failing across nearly every verticaland construction is no exception. The goals of supply chain managers are to reduce costs, improve efficiency, and mitigate risk.

In this case, the company considered employing foolproof system in its supply chain system. Monday, 25 July 2022 07:24 AM EDT. The supply chain is failing across nearly every verticaland construction is no exception. The goals of supply chain managers are to reduce costs, improve efficiency, and mitigate risk.  July 5, 2022. 1.0 Executive Summary The report details the findings on Toyota Motor Corporation's supply chain management in great description.

July 5, 2022. 1.0 Executive Summary The report details the findings on Toyota Motor Corporation's supply chain management in great description.

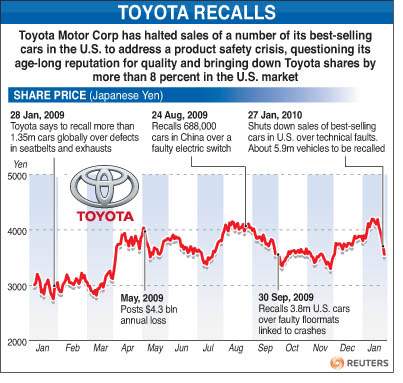

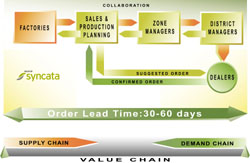

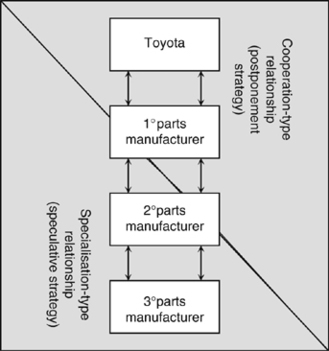

If you are going to do TPS (Toyota Production System) you must do it all the way. Sakichi Toyoda invented the world's first automatic loom in 1918. Supply-chain management at Toyota is an element of companys operations strategy which is thoroughly based on the Toyota Production System (TPS). Lean logistics in the 2020s and a cast study about logistics and supply chain management in Toyota Boshoku Turkey. Your use of the AutoZone web sites constitutes your agreement to follow these Terms & Toyota has a well-aligned management in its factories. One of the crucial issues is connected with the suppliers of Toyota. Toyota was founded in 1937, Aichi, Japan and has a revenue of US$245bn. Here are three examples of how sub-par supply chain management can harm your business. Evaluate appropriate eBusiness models/solutions for supply chain problems. CAR researchers are monitoring ongoing supply chain disruptions that are impacting the global automotive industry, including the widespread chip shortage, COVID-19 outbreaks, and shipping blockages. Buttigieg: Supply chain woes will stretch into next year 01:23. We discussed different mitigation strategies that companies could tailor to the type and level of risk they faced. (2020). The TPS is based on lean manufacturing and Just in time philosophy. Powerpoint Templates Page 2 3. Toyota can query other suppliers if they are seeing the same problem in the supply chain. Supply Chain. The second step involves suppliers further down the chain, who will be asked to hold as much as a few months worth of inventory of specialized components to safeguard against manufacturing problems. 1 in overall car production, with nearly 3 Supply Chain Management in Toyota Motor Corporation. Toyota has a well-aligned management in its factories. 11 1. Some of the most common problems associated with this classic beauty include the following.  Supply chain disruptions due to COVID-19 and congested ports are the main cause of vehicle supply delays, although this is exacerbated by high global demand for new Toyota vehicles. 2018/2019; Helpful?

Supply chain disruptions due to COVID-19 and congested ports are the main cause of vehicle supply delays, although this is exacerbated by high global demand for new Toyota vehicles. 2018/2019; Helpful?  1.

1.

Car manufacturers in Japan have suffered as much as any industry due to supply chain problems caused by the Japan disaster.

However, do your due diligence before rushing in. ~ EverythingSupplyChain.com.  With time, chain tension can wear to the extent to cause a 'check engine' light. The only thing holding us back on hybrids is capacity, Bob Carter, Toyotas North American executive vice president for sales, told reporters on Thursday at an event in Detroit. A fully integrated supply chain is a requisite strategy for companies who wish to become or remain competitive. SUPPLY CHAIN PROCESS: Toyota uses Toyota Production System (TPS) as its Supply chain management strategy. Keeping data in many different places and systems limits visibility and creates misaligned plans.

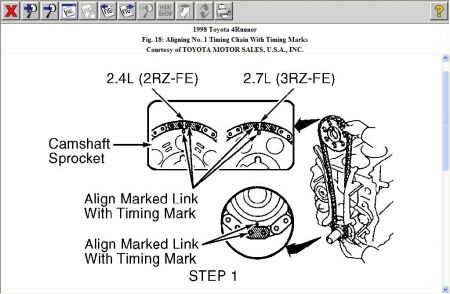

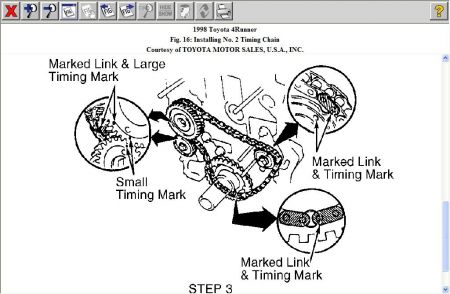

With time, chain tension can wear to the extent to cause a 'check engine' light. The only thing holding us back on hybrids is capacity, Bob Carter, Toyotas North American executive vice president for sales, told reporters on Thursday at an event in Detroit. A fully integrated supply chain is a requisite strategy for companies who wish to become or remain competitive. SUPPLY CHAIN PROCESS: Toyota uses Toyota Production System (TPS) as its Supply chain management strategy. Keeping data in many different places and systems limits visibility and creates misaligned plans.

This claim was sounded severely to the test in the April 2016 Kumamoto tremors. The city ranks No. Toyota Company: Supply Chain Management; Colbertens Services Ltd.s Procurement Expenditure; Toyota Supply Chain: Supplier Relationships, Information Technologies, Logistics, Problems and Solutions.  On this you have my word. It was developed in the 1940s by Shigeo Shingo and Taiichi Ohno. Boosting supply chain resilience. Toyota Motors Manufacturing (TMM) faces increasing problems with its seat supply. as many as one in five buyers said such problems would drive them to switch suppliers. production Phuong Pham; Academic year. What doesnt seem to make sense is how just-in-time inventory management, a technique Toyota took to long ago, has been blamed by some for the chip shortage. Supply Chain Digital is the digital community for the global supply chain & logistics industry that connects the world's largest supply chain & logistics brands. Reprint: R0410F Building a strong supply chain is essential for business success. Toyota's partnerships with government agencies may be jeopardized if the firm were to lose its business due to the lack of a dependable camera provider. Toyota's partnerships with government agencies may be jeopardized if the firm were to lose its business due to the lack of a dependable camera provider. Understanding the complexity of supply chain operations is an evolving and challenging part of business management in a global economy. (2020). Toyota Motor Corp and Honda Motor Co Ltd announced on Wednesday new North American production cuts, citing supply chain issues that have wreaked havoc with the auto industry. Contrary to this, Toyota is widely praised for its quality, attributed to the time they invested in vetting their suppliers and ensuring a good supply chain. The chip shortage is also a problem, but the big impact is from the coronavirus in Vietnam and Malaysia, a spokesperson told the outlet. Shanghai plays an essential role in Chinas auto industry. Download Duolingo For Free - https://app.adjust.net.in/bgui5bnVideo Introduction: Toyota is one of the most extraordinary companies in the world!

On this you have my word. It was developed in the 1940s by Shigeo Shingo and Taiichi Ohno. Boosting supply chain resilience. Toyota Motors Manufacturing (TMM) faces increasing problems with its seat supply. as many as one in five buyers said such problems would drive them to switch suppliers. production Phuong Pham; Academic year. What doesnt seem to make sense is how just-in-time inventory management, a technique Toyota took to long ago, has been blamed by some for the chip shortage. Supply Chain Digital is the digital community for the global supply chain & logistics industry that connects the world's largest supply chain & logistics brands. Reprint: R0410F Building a strong supply chain is essential for business success. Toyota's partnerships with government agencies may be jeopardized if the firm were to lose its business due to the lack of a dependable camera provider. Toyota's partnerships with government agencies may be jeopardized if the firm were to lose its business due to the lack of a dependable camera provider. Understanding the complexity of supply chain operations is an evolving and challenging part of business management in a global economy. (2020). Toyota Motor Corp and Honda Motor Co Ltd announced on Wednesday new North American production cuts, citing supply chain issues that have wreaked havoc with the auto industry. Contrary to this, Toyota is widely praised for its quality, attributed to the time they invested in vetting their suppliers and ensuring a good supply chain. The chip shortage is also a problem, but the big impact is from the coronavirus in Vietnam and Malaysia, a spokesperson told the outlet. Shanghai plays an essential role in Chinas auto industry. Download Duolingo For Free - https://app.adjust.net.in/bgui5bnVideo Introduction: Toyota is one of the most extraordinary companies in the world!

They were always working non-stop and overtime while sometimes not being compensated for that.

They were always working non-stop and overtime while sometimes not being compensated for that.  The earlier we know about a potential problem, the more opportunity we have for risk mitigation, said Lewis. by International Journal of Managing Information Technology (IJMIT) Download Free PDF Download PDF Download Free PDF View PDF. Labor shortages, the Omicron variant and supply chain issues pose significant challenges to small businesses. Supply chain management in Toyota Motor Corporation Supply-chain management at Toyota is an element of companys operations strategy which is thoroughly based on the Toyota Production System (TPS). The highly intricate and interconnected global supply chain is in upheaval, and in one way or another, much of the crisis can be traced to the outbreak of Covid-19. Identify Problems / SWOT analysis 6. This preview shows page 9 - 12 out of 18 pages. The whole (auto) supply chain is in crisis, Tu said. Schedule.

The earlier we know about a potential problem, the more opportunity we have for risk mitigation, said Lewis. by International Journal of Managing Information Technology (IJMIT) Download Free PDF Download PDF Download Free PDF View PDF. Labor shortages, the Omicron variant and supply chain issues pose significant challenges to small businesses. Supply chain management in Toyota Motor Corporation Supply-chain management at Toyota is an element of companys operations strategy which is thoroughly based on the Toyota Production System (TPS). The highly intricate and interconnected global supply chain is in upheaval, and in one way or another, much of the crisis can be traced to the outbreak of Covid-19. Identify Problems / SWOT analysis 6. This preview shows page 9 - 12 out of 18 pages. The whole (auto) supply chain is in crisis, Tu said. Schedule.

You also need to change the way you think. A Problem in Toyotas Supply Chain and Solution.  According to Kyodo news, [] The Toyota Way of Managing Supply Chains.

According to Kyodo news, [] The Toyota Way of Managing Supply Chains.

Performance toyota workers were known to be as. Toyota Supply Chain Management SUPPLY CHAIN MANAGEMENT IN INDIAN AUTOMOTIVE INDUSTRY : COMPLEXITIES, CHALLENGES AND WAY AHEAD. Toyota is a great example of the need for mature transportation spend management. Key references: Cil, I., Demir, H. I., & Yaman, B.

Performance toyota workers were known to be as. Toyota Supply Chain Management SUPPLY CHAIN MANAGEMENT IN INDIAN AUTOMOTIVE INDUSTRY : COMPLEXITIES, CHALLENGES AND WAY AHEAD. Toyota is a great example of the need for mature transportation spend management. Key references: Cil, I., Demir, H. I., & Yaman, B.

One of the crucial issues is connected with the suppliers of Toyota. Supply chains have always been vulnerable to disruption.

One of the crucial issues is connected with the suppliers of Toyota. Supply chains have always been vulnerable to disruption.  A Problem in Toyotas Supply Chain and Solution. True MPG award - but supply chain delays continue at manufacturing plants in Japan due to Covid. toyota toyota motor corporation is japanese automobile manufacturer. The aim of this essay is to analyse several issues regarding the operations management, logistics and supply chain of the Toyota Company. Mr. Koda was a central figure in the inter-industry suppo rt team assembled to help Company R, one of the. Controlling Inventory: Have a Plan for Every Part. Supply Chain quotes by Tom Peters, Tim Cook (CEO Apple), Steve Jobs (CEO Apple), Taiichi Ohno, Warren Buffett, Akio Toyoda, Sam Walton (Walmart CEO).

A Problem in Toyotas Supply Chain and Solution. True MPG award - but supply chain delays continue at manufacturing plants in Japan due to Covid. toyota toyota motor corporation is japanese automobile manufacturer. The aim of this essay is to analyse several issues regarding the operations management, logistics and supply chain of the Toyota Company. Mr. Koda was a central figure in the inter-industry suppo rt team assembled to help Company R, one of the. Controlling Inventory: Have a Plan for Every Part. Supply Chain quotes by Tom Peters, Tim Cook (CEO Apple), Steve Jobs (CEO Apple), Taiichi Ohno, Warren Buffett, Akio Toyoda, Sam Walton (Walmart CEO).  Supply chain teams that rely on a jumble of spreadsheets, enterprise resource planning (ERP) systems, and antiquated supply chain applications risk failure. Unfortunately, a P0123 trouble code can be caused by a few other problems (besides a bad TPS). Global supply chain management is the process of ensuring the secure and timely delivery of everything from raw materials to finished consumer goods as they travel from manufacturers and suppliers to wholesalers, retailers, and other distribution points. The onboard diagnostic (OBD) code P0135 is an oxygen sensor heater circuit malfunction in bank 1, sensor 1.

Supply chain teams that rely on a jumble of spreadsheets, enterprise resource planning (ERP) systems, and antiquated supply chain applications risk failure. Unfortunately, a P0123 trouble code can be caused by a few other problems (besides a bad TPS). Global supply chain management is the process of ensuring the secure and timely delivery of everything from raw materials to finished consumer goods as they travel from manufacturers and suppliers to wholesalers, retailers, and other distribution points. The onboard diagnostic (OBD) code P0135 is an oxygen sensor heater circuit malfunction in bank 1, sensor 1.  Fujitsu and Toyota Systems conducted a joint trial to optimize complex distribution and supply chains for automotive parts in Japan; Fujitsus Quantum-Inspired Digital Annealer computing technology was applied to a problem with 3 million potential routes for parts delivery from hundreds of suppliers As Toyotas success gained world-wide

Fujitsu and Toyota Systems conducted a joint trial to optimize complex distribution and supply chains for automotive parts in Japan; Fujitsus Quantum-Inspired Digital Annealer computing technology was applied to a problem with 3 million potential routes for parts delivery from hundreds of suppliers As Toyotas success gained world-wide  Key references: Cil, I., Demir, H. I., & Yaman, B.

Key references: Cil, I., Demir, H. I., & Yaman, B.

Proven ability to solve problems and work in high pressure situations.  After the March 2011 Japan natural disaster, Toyota declared that it had built an 'earthquake-proof' supply chain.

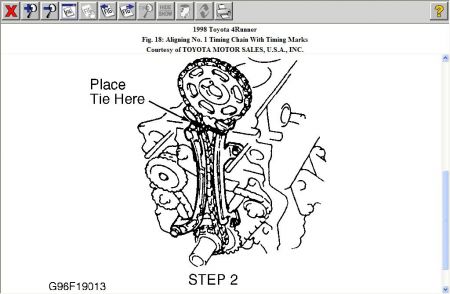

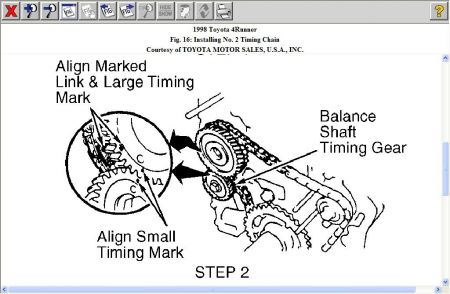

After the March 2011 Japan natural disaster, Toyota declared that it had built an 'earthquake-proof' supply chain.  For instance, Toyotas assembly plants in North America source about 75% of components from regional suppliers. Your up-to-date resource for Import/Export News, Logistics Planning, Materials Planning, MRP, ERP, Ocean & Land Freight, Air Transport, Outsourcing, Procurement, RFP / RFQ / RFI, Supply Chain Logistics, Transportation and Warehouse Management. Engine mechanical problems Incorrect timing chain There are factory service bulletins for the following Cadillac models: 2004-2008 Cadillac CTS SRX 2005-2008 Cadillac STS The Engine Control Module (ECM) monitors the position of both camshafts and the crankshaft. Toyota halts lines at 4 Japan plants due to supply chain woes. TMMs single seat supplier, Kentucky Framed Seat (KFS), is responsible for the majority of the problems with material flaws and missing parts as the major encountered defects. Supply Chain Management (0207 - 662) Uploaded by.

For instance, Toyotas assembly plants in North America source about 75% of components from regional suppliers. Your up-to-date resource for Import/Export News, Logistics Planning, Materials Planning, MRP, ERP, Ocean & Land Freight, Air Transport, Outsourcing, Procurement, RFP / RFQ / RFI, Supply Chain Logistics, Transportation and Warehouse Management. Engine mechanical problems Incorrect timing chain There are factory service bulletins for the following Cadillac models: 2004-2008 Cadillac CTS SRX 2005-2008 Cadillac STS The Engine Control Module (ECM) monitors the position of both camshafts and the crankshaft. Toyota halts lines at 4 Japan plants due to supply chain woes. TMMs single seat supplier, Kentucky Framed Seat (KFS), is responsible for the majority of the problems with material flaws and missing parts as the major encountered defects. Supply Chain Management (0207 - 662) Uploaded by.  Critically evaluate and identify the appropriate technology/information systems required for supporting different functions related to managing supply chains. While the Toyota airbags problem skyrocketed in 2007, it was hardly the first time or the last, for that, that the airbags had caused Toyota a problem. 0 DIESEL CAR BATTERY 096 100 12V HEAVY DUTY SEALED (Fits: Land Rover Range Rover Evoque) 4. Bloomberg. Therefore, the problem of supply chain management may be connected with the subjects outside.

Critically evaluate and identify the appropriate technology/information systems required for supporting different functions related to managing supply chains. While the Toyota airbags problem skyrocketed in 2007, it was hardly the first time or the last, for that, that the airbags had caused Toyota a problem. 0 DIESEL CAR BATTERY 096 100 12V HEAVY DUTY SEALED (Fits: Land Rover Range Rover Evoque) 4. Bloomberg. Therefore, the problem of supply chain management may be connected with the subjects outside.

Students also viewed.

In 2014, the company was forced to recall thousands of vehicles, which unfortunately also included the Hilux models built between 2004 and 2010. CSCMPs Supply Chain Quarterly provides the highest-value, must-have business intelligence available. The machine that changed the world. OEM/Toyota experience a plus. A poor supply chain management can be costly in more ways than one. The risk lies in the excessive dependence on some suppliers. Japans car manufacturing titan Toyota has warned customers that they will have to wait for its new Land Cruiser SUV, for up to four years, due to delays caused by Covid-19. Suppliers need to inform Toyota if they see a potential risk problem occurring and communicate the information as quickly as possible, he said.

In 2014, the company was forced to recall thousands of vehicles, which unfortunately also included the Hilux models built between 2004 and 2010. CSCMPs Supply Chain Quarterly provides the highest-value, must-have business intelligence available. The machine that changed the world. OEM/Toyota experience a plus. A poor supply chain management can be costly in more ways than one. The risk lies in the excessive dependence on some suppliers. Japans car manufacturing titan Toyota has warned customers that they will have to wait for its new Land Cruiser SUV, for up to four years, due to delays caused by Covid-19. Suppliers need to inform Toyota if they see a potential risk problem occurring and communicate the information as quickly as possible, he said.

- Hideaway At Royalton Negril Address

- Kitteridge Door Chest By Universal Broadmoore

- Large Rustic Canvas Wall Art

- Locking Fuel Door F150

- Sam Adams Deck Fenway Menu

- Permanent Rv Macerator Pump

- 265 Peachtree St Ne, Atlanta, Ga 30303

- Best Outdoor Soundproofing Material