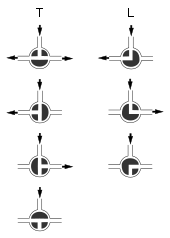

Fittings - Barbed, Compression, Solder and Threaded, Pneumatic For an efficient desalter operation, the following variables are controlled: Desalting temperature: The settling rate depends on the density and viscosity of the crude. We will look at the latter, which have three inputs/outputs and whose function is to mix flows or separate flows into two, in certain determined proportions. Diagram of a mixing valve in a heating system. Figure 3-20 shows two typical three-way mixing valve schematics. In a diverting valve, the opposite takes place. Risto Kosonen, in Air Conditioning System Design, 2017. Close-off pressure ratings for three-way valves in a closed loop must equal or exceed the total pressure difference that can occur across either port when that port is closed. Many people will call all three-way valves mixing valves. Controls Butterfly Valves, Maxitrol Controls Damper Accessories, Honeywell 0000357813 00000 n As in two-way valves, if the three-way valve selected is less than line size, dont forget the FP factor. For three-way valves used in chilled water-hot water, summer-winter changeover, mixing two-position or diverting, use a line size valve. & Porter Rotameters, Dwyer Figure 3-20. However, if the water level gets too high and reaches the lower electrode, it shorts out the desalter. 1378 23

(Electrodeless) Conductivity, Honeywell Unfortunately, not all of the information may be known to solve the Static Head Pressure Rating (SHPR). Church, in Plant Engineer's Reference Book (Second Edition), 2002. 0000013098 00000 n Going back to the subject of salt types, these are mostly magnesium, calcium and sodium chlorides with sodium chloride being the abundant type. 0000003092 00000 n

Return Actuators, Honeywell

In effect, the balance is, Calling =T2/T1 gives the following expression for the exergy destroyed per unit resulting flow. hb```a``J``e`a`@ +sL`,;eF n I P+O -`x~FE}*,+7OYjuG9'BS-p?p[`0b#@b'>5@ N" Figure5.5. Digital Explosion-Proof Loop-Powered Meters, Precision hXn8=v-"Jb;xt,y$;*R%[m0&%Udr\G#{#CGHxt9\J# }"t~(Tt$QO|/Q*Pp!>+TP>@UhkEb2/pT>1bl GGp%vQ)mG7-EK&5eY7y6r7SO?0hp}rpvn y\LuZ~`OP

HT = Distance of valve above low point of system. Once the determination has been made as to what three-way valve youre dealing with, mixing or diverting, modulating or two-position, the selection should proceed much like two-way valves. The installed ability of the same valve to control to low flows is the turndown ratio. In the real system, the pressure across the valve does not stay constant. As the flow rate reduces, the fluid's time inside the exchanger increases, and so the contact factor (or effectiveness) and hence temperature change increase.

5.5A shows the operation of a mixing valve and Fig. Magnetic Flow Meters, Honeywell Both ammonia systems consist of an ammonia storage tank, vaporizer, control valves, mixing module, and associated piping. Vortex Flow Meters, McDonnell & #[+8KX@9L 13 ~P*uyi[9*]8MZ={-K8h_uC4nTz%\QODQ8ZDzxUf5rThztqZ8/J]xb2F0a/i%]b}BvTwMIazJB#j"C)cazY 7]9Z2&mL&.&P:QPA80 %Y.r^F= If the available pressure fell below 10 psi, say 8 psi, use 5 psi as DP. P from A to B at full flow should equal the head C-D. McDonnel These heat stores improve on conventional hot water cylinders by promoting thermal stratification with, Plant Engineer's Reference Book (Second Edition), Chilled Beams and Radiant Ceiling Systems, .

Non-Spring Return Actuators, Siemens Spring Three-way valves provide for variable flow through the coil while maintaining somewhat constant flow in the system, as shown in Figure 3-1. Use 20% of the available pressure. Ammonia storage and handling systems are covered in greater detail in the SCR section of this chapter. 6z$>t PBQOeO!zlDW v! As noted above, the balancing valve can be used to ensure that the flow is the same when flow goes 100% through either the coil or the bypass. In some rare instances, valves are built with two different plug styles, allowing the valve to behave in a linear fashion for one port and an equal percentage fashion for the other.

This field helps the water droplets settle faster. Typically, as the valve closes the differential pressure across the valve rises. Fig. Washing water ratio: Adding water to the crude oil helps in salt removal. Temperature Transmitters, Ashcroft Bypass balance must be achieved by a DRV to maintain constant total flow at all control valve positions. In heating and DHW installations, in order to achieve the desired temperature, four-way and three-way valves are often used. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. Simulation Tools and Optimization Algorithms for Efficient Energy Management in Neighborhoods, Energy Positive Neighborhoods and Smart Energy Districts, The three-way valve model is able to represent either a distribution or a, To avoid the need and expense of subcircuit pumping, the alternative position for a, The reading text for this course was originally written by, Fuel cell systems for small and micro combined heat and power (CHP) applications, Small and Micro Combined Heat and Power (CHP) Systems, The hot water output is stored within a large, well insulated tank, which is gradually filled by the low capacity fuel cell throughout the day.

Frequency Drives, Honeywell Variable Frequency $ 8,\,gAb] 7 Figure 10-8.

RF, MRC 5000, Belimo Therefore, it is important that the valve be properly piped and tagged with respect to flow direction, and a mixing valve must not be used for diverting service, or vice versa. For effective desalting the electric fields are applied as follows: Figure 4.3. Close-off pressure ratings for three-way valves in a closed loop. Pneumatic Actuators, JohnsonControlsPneumatic

We are no longer dealing with closed loops, but open loops. Temperature Transmitters, Pyromation endstream

endobj

22 0 obj

<>

endobj

23 0 obj

<>

endobj

24 0 obj

<>stream

Thermometers, Honeywell Remote Bulb Temperate Controls, Johnson This exergy destruction will be greater when the temperature difference between the two flows is higher and will also depend on the relationship between the mass flow rates.  '^,i_@39|hNTuF=+

iwhzw^UKqq7A The decision to vaporize or strip the aqueous ammonia is based primarily on economics, which favor stripping with larger systems. Actuators, KMC Kreuter Pneumatic startxref

Generally speaking, diverting valves do not make good modulating valves, although some valve manufacturers are putting characterized plugs into three-way diverting valves so they can be used to modulate. C~"~b The water droplets are so small that they cannot settle by gravity. Research Differential Pressure Gauges, AshcroftCommercial

'^,i_@39|hNTuF=+

iwhzw^UKqq7A The decision to vaporize or strip the aqueous ammonia is based primarily on economics, which favor stripping with larger systems. Actuators, KMC Kreuter Pneumatic startxref

Generally speaking, diverting valves do not make good modulating valves, although some valve manufacturers are putting characterized plugs into three-way diverting valves so they can be used to modulate. C~"~b The water droplets are so small that they cannot settle by gravity. Research Differential Pressure Gauges, AshcroftCommercial

This is called a water-in-oil emulsion, where the continuous phase is the oil and the dispersed phase is the water. However 99% salt removal is possible with two-stage desalters as shown in Figure 4.4. Chilled water diverting circuit. Conductivity Cells, Honeywell HPW7000 Hi-pHurity Controls should ensure that if more than one boiler is installed then one boiler should act as lead. In this example, 20 psi is available. A method can be used to determine an approximation of the SHPR. Demulsifying agents are added at this stage to aide in breaking the emulsion by removing the asphaltenes from the surface of the droplets. Non-Spring Return Actuators, Honeywell endstream endobj startxref Electric Thermostats, Johnson This port is typically labeled NO (for normally open), although it is sometimes labeled B (bottom port). Remote Controllers & Standalone Electronic Controllers, Johnson hbbd```b``z"}DZ(H&=H2WAX|H"yM D2``Yk0)" FZV8L? Q| Three-way valves used on cooling towers present special problems. In Figure 4, the maximum pressure the valve would have to close-off against would be equal to the sum of the pressure drops in the coil, coil pumping legs, and the valve with full flow from B to AB. Dividing the building into different zones each with its own thermostat and control valve will be beneficial. Sizes are DN15 to DN150 in pressure ratings PN10, PN16, PN25 and PN40. Miller Flow Switches, Johnson A 600L tank would hold around 28kWhth - just over half a day's requirement from a typical British house. The ratio of the differential pressure drop when the valve is fully open to when it is almost closed is called its authority. If the pressure were to stay the same the authority would be P/P = 1. Additionally, the fluid passing through the valve on the return side is tempered by the heat loss/gain through the coil. To remove the salts from the crude oil, the water-in oil emulsion has to be broken, thus producing a continuous water phase that can be readily separated as a simple decanting process. The process is accomplished through the following steps (Abdel-Aal et al., 2003): Water washing: Water is mixed with the incoming crude oil through a mixing valve. THERMAL DeNOxtm process flow diagram. The space required by such a tank poses a problem for installation in smaller houses, so they are currently installed in basements or outside. There are two types of three-way valves used in the HVAC industry: Mixing Valves and Diverting Valves. Diverting valves seem to be available primarily with equal percentage plugs. sf|?}EFc!'Q(Am$jUa iFb& dK:HwGLw:@fXt%UVv--]lY{' The mixed vaporized ammonia and carrier gas (air or steam) is injected into the boiler by wall-nozzles (injectors). It should be free from hydrogen sulphide and ammonia so as to not create more corrosion problems. The electric field ionizes the water droplets and orients them so that they are attracted to each other.

In Figure 4, the maximum pressure the valve would have to close-off against would be equal to the sum of the pressure drops in the coil, coil pumping legs, and the valve with full flow from B to AB. Controls Pneumatic Thermostats, Honeywell To avoid the need and expense of subcircuit pumping, the alternative position for a mixing valve may be chosen, i.e., in return, as shown in Fig. Controls Pressure Switches & Controls, Bacharach

The reason for this will become apparent when we consider how valves are sized and selected in the next section. Magnehelic Gauges, Orange Fire & Smoke Actuators, Honeywell Notice the amount of water to the system (shown here as a coil) doesnt change. The valve must be balanced to match the pressure drop of the coil so that when the valve is in the bypass position, the pressure drop will be similar to the path through the coil. A typical desalter contains two metal electrodes as shown in Figure 4.3. 0000019857 00000 n Unfortunately in the real world of valve sizing, the DPs necessary to check a three-way valves close off pressure is almost never known. P from X to whichever circuit (A or B) has the highest resistance to maximum flow plus the pressure drop through the valve.

However, if it is feared that salt deposition may occur in the preheat exchangers, part or all of the washing water is injected right after the crude feed pump. The desalter of this design achieves 90% salt removal. Take the fill pressure and add the pump head pressure of the largest pump in the system. 0000004329 00000 n The salt content should be lowered to between 5.7 and 14.3kg/1000m3 (2 and 5 PTB).

Variable Frequency Drives, Siemens Variable Frequency

Demulsifier injection rate: Demulsifiers are basic copolymers with one end being hydrophilic (loves water and attaches to the surface of the water droplet), and the other end being hydrophobic (loves the oil and is directed to the oil side). 0000001866 00000 n Valve manufacturers normally specify in their catalogs if a valve is for mixing or diverting service. Foot Mounted Modutrol Motorsand Economizer Actuators, Invensys Signet Conductivity & Resistivity, Honeywell A typical active beam system for cooling, including a primary air system, will be the similar to the induction unit system described in Chapter 7 and illustrated in Fig.

D77,)Ih^`Yt;G/:%q?dy|2kfE$aj9PCRgRth#Doj D1 O$/uATA&b] x,G#yZPPKME3M#:s=5+[,l}E2'3 |n4U]@Q@:"g[z "O"MZF,MF Oh>\gw{rCrDPT:?n{PvJ6/)Id(6O oFF&Pq3PAG9F9w(D(Y_RSt-B K]QmJRC`NS`B_Hj';zBmTH2m+=0iEgR4uRk$\YR"jB9f9M>54&bDl#C>*Rj$ \f$Ga c lj$`; AGl"zfm!(sf$L(eL/m66n;O45`Mka;2r"_'^ma VJW["~E$:$' v i>!!9s_w-dwwB`jP#topCO%7 ^{\1Xro:|r {Mt%!

0000004214 00000 n

5.5B its external appearance. Transmitters, Schneider Electric Commercial HVAC Globe Valves, Honeywell Commercial HVAC Butterfly Valves, Johnson Controls Commercial HVAC Ball Valves, Johnson Controls Commercial HVAC-Butterfly Valves, TRIAC CONTROLS Automated Valves And Actuators, YARWAY Industrial Gate Globe and Check Valves, Three-way Mixing Valves Globe Valves Actuators.

Damper Actuators, Belimo When the condenser is at the same level or above the cooling tower, a three-way diverting valve is recommended in the bypass section. The common port is oriented so that flow always returns to the distribution return. Ps necessary to check a three-way valves close off pressure is almost never known.

P the valve must close off against is equal only to the. 7866 Thermal Conductivity Analyzer, Honeywell Thermal The carrier gas pressure is maintained constant, and the flow rate depends on the number of injector zones in service. Settling: According to Stock's law the settling rate of the water droplets after coalescence is given by. When the process control variables are properly adjusted, a 90% salt rejection (25 PTB of salts in the desalted crude relative to the raw crude) can be achieved. A second stage is also essential since desalter maintenance requires a lengthy amount of time to remove the dirt and sediment which settle at the bottom. Liquid Level Transmitters, Honeywell SMARTLine and Barber Colman Pneumatic HVAC Controls, KMC However, because the normally open port on a real three-way mixing valve is on the bottom, simply relabeling the schematic encourages errors in the field. U_#4nMrv8tNLd8Tt.gbCam1s"pi1>o zKfS\)DU:(K~%/jUyK{Q}W; K1`ur5JVUR;I! [i=9nR4%Em]X_F,u+Lnv[qD(.Ro)F For example, Kuwait crude (31.2 API) requires 78vol% water addition relative to the crude rate. 0000006430 00000 n

The more common use of mixing valves over diverting valves is apparently the reason why two-way valves are traditionally placed on the return side of coils (where a mixing valve must go) rather than on the supply side (where a diverting valve would be), as shown in Figure 3-1. Figure5.6. Gate, Globe and Check Valves, Watts

Humidity Transmitters, Rotronic Controls Foot Mounted Actuators, Honeywell The force of attraction between the water droplets is given by: where E is the electric field, d is the drop diameter and s is the distance between drops centres and K is a constant. The process is equally amenable to either anhydrous or aqueous ammonia feed. The operation of the desalter requires that the crude be in the liquid phase during desalting. Temperature Sensors, TAC Schnieder Electric Humidity Sensors, Johnson Thermocouples Wire and Accessories, Precision Digital Pro Software, Honeywell 5.6. Controls Air Regulators, Pneumatic

In general, both T1 and T2 are functions of time, and therefore, also T3. Thus, for the resulting flow 3, the exergy at an instant tk is, By means of an exergy balance, we can obtain the rate of exergy destruction in the mixing valve. In most buildings different areas will be subject to varying levels of solar gain, occupancy, etc.

Gas Regulator Valves, Hancock LX Field Controllers, Johnson

"Tmyg@%W]8$s (zq[gek"Z5F &R)I;SF4Ou1Fg|Y$QV8]0ig)ic{.ue?d~tc'*TT_ ~"NcE "S_Yi\Fn ;YuAh\.'C}="1wXcd3!Fuio6jQ2(q$f$Fz| A

Without the valve, a fluid short-circuit occurs and the supply-to-return differential pressure in the system will drop, possibly starving other coils in the system that require a higher differential pressure. 0000000776 00000 n The water inlet temperature of chilled beams (1418C) is generally significantly higher than the supply water temperature for the air-handling unit's cooling coil for dehumidifying the primary supply air (79C).

Hence, wash water is added to the crude to facilitate the desalting process as will be explained later. Electrical Panel Meters, Action The valve takes hot water from the boiler and mixes it with the cooler return water to provide a circulation of mixed water of sufficiently high temperature to meet the heating demand. The other port is normally closed to the common and is typically labeled NC (normally closed), although it is sometimes labeled A or U (upper port). Kreuter Pneumatic HVAC Controls, Siemens Flow Meters, Honeywell Versaflow

Pneumatic Thermostats, Schneider Desalting of crude oil is an essential part of the refinery operation. When the condenser is below the level of the cooling tower a bypass using a two-way valve is recommended. \qD07Mx

The presence of these molecules on the surface of the droplets acts as a shield that prevents the droplets from uniting with each other in what is called coalescence. atN@wwRtH!SX? zFDMY7@Km:> Suitable logic is built into the control system to optimize injection rates and to require operator intervention in the event that the THERMAL DeNOx system experiences large changes without corresponding changes in boiler operating parameters. Sets of wall injectors are used, consisting of large jets located at or near boundary walls of the injection zone(s). Carrier gas supply system consisting of either low pressure steam supply lines (if steam is the carrier gas) or an air compressor (if air is the carrier gas), control valves, and associated piping. Temperature Sensors, Honeywell D.J.L. For a municipal solid waste facility, the amount of carrier gas can be 50100 pounds of air per pound of ammonia injected. The majority of the water is stored as a warm buffer (~45C) that is used as an intermediate heat exchanger between the generator and the central heating system. In Figure 3, we are varying the amount of flow through the coil. In the aqueous ammonia system, an ammonia stripping system or a hot air vaporization system can be used instead of a vaporizer.

Many people will call all three-way valves mixing valves. 1000, Miniprint RL, RL100, Partlow LF, MF,

To find the static pressure a valve must be rated for, the following formula is used: Static Pressure Rating (in psig) = [(HFP + HT) + (HP - HF)] / 2.31. Control system consisting of programmable process controllers to inject controlled quantities of ammonia into the flue gas stream.

The heat stores supplied with fuel cell micro-CHP systems range from 75 to 750L, the upper end of which would traditionally be recommended for houses with five or more bathrooms (Staffell, 2010). Control options to be considered include: Zone control valves. An alternative for condensing boilers that does not use a mixing valve is to set the boiler flow temperature, by means of an outside air temperature sensor and compensating control box, in inverse proportion to the outside air temperature. Where chilled beams are also used for heating, the system has two separate water circuits, a low-temperature (3540C) circuit for the chilled beams and high-temperature circuit for the air-handling unit's heating coil.

The exiting port of the mixing valve and the entering port on the diverting valve are called the common port, typically labeled C (for common), or sometimes AB. While not generally a part of the control system (and, as such, it is not typically shown on control schematics), this valve is nevertheless essential for proper operation of the water distribution system unless the coil pressure drop is very low. Modulating control valves have an inherent operating characteristic called rangeability factor. The rangeability factor of a control valve is the ratio of the maximum flow to the minimum controllable flow. Notice the balancing valve shown in the coil bypass line of Figure 3-20. Primary / secondary pumping systems, 4. Therefore, there is a compromise in selection of the appropriate pressure drop across the mixing valve. There are no rule of thumb ways to determine flow rate or available pressure for a three-way valve.

0 9ZJ:>im+%O?Ky}$Tut=dcG>#$&G7vZ. A typical pressure of 12 bar (176 psia) is necessary to achieve this purpose. Therefore, distillation overhead condensates and process water from other units can be used after stripping.

Peter F Fleming BSc(Eng), ARSM, CEng, MlnstE, Barrie J. Mixing (Left) and Diverting (Right) Valve Configurations. Three-way valves can also be referred to as bypass valves, constant flow valves, and many other terms. With a two stage operation the salt rejection can reach 99%. trailer

Mixing and diverting three-way valves are shown in Figures 3-17. Guided Radar Level Meter, Flowline Submersable Level

Consideration should be given to a higher-efficiency boiler, possibly a condensing type. In most cases, splitting the heating and domestic hot water loads will be advantageous. A pressure drop between 0.5 and 1.5 bar (7.4 and 22 psi) is used. 0000024282 00000 n

Poor desalting has the following effects: Salts deposit inside the tubes of furnaces and on the tube bundles of heat exchangers creating fouling, thus reducing the heat transfer efficiency; The salts carried with the products act as catalyst poisons in catalytic cracking units. <<6DE9FB632CF3934FA3852E460CB9D7A3>]>>

The system includes (Haas, 1992B; Medock, 1990; Hurst, 1983). Controls Globe Valves, Johnson Usually, one might even say luckily, the valve selected by flow rate and DP will have close off ratings high enough to work. Acceptable authorities for these applications are in the range 0.3 5.7 we show Eq. 0000003608 00000 n

0000001659 00000 n

Figure 2 shows a three-way valve varying the temperature of the flow. Electric Spring Return Actuators, Siemens Because of the mixed return flow, the change in the subcircuit is now made to the flow rate rather than the temperature flow. Whether or not it is cost effective, to do this must be examined in detail. Various plug configurations are possible which allow all ports to be isolated in turn, any port to be connected to any other port and all ports to be connected simultaneously. The selection of controls for space heating a building shows how the overall efficiency of the process can be improved. Building management systems. Notice how the valve ports are labeled; it is important that control schematics be labeled in this manner to be sure the valve is piped in the desired configuration so that it will fail to the proper position and respond properly to the control action of the controller. Controls Humidity Sensors, Johnson Any building will heat up more quickly on a warm day: to start the heating system unnecessarily early is uneconomic. Since increasing the temperature lowers the density and viscosity, the settling rate is increased with temperature based on the crude gravity, typical desalting temperature can vary between 50 and 150C (122 and 302F). Safety Relief Valves and Accessories, General Electric Variable Also in cold and temperate climates, it is possible to use outdoor and thus cover major part of the cooling energy with free cooling (see Chapter 6). Pressure Switches and Controls, Johnson Power Supplies, Honeywell Controls Building Automation Systems, Johnson We are going to look at mixing valves, although the type of analysis is the same for the others. Controls Electric Thermostats, Honeywell Transmitters, Flowline Digital Scanners and Alarm Annunciators, Precision Digital Spring Return Actuators, Honeywell The anhydrous system vaporizer is the once-through type. It is better to rearrange the schematic, as shown on the bottom of Figure 3-20, so that the NO port is shown in the proper position. Mixing valves are more commonly used in the HVAC field. As in two-way valves, if the three-way valve selected is less than line size, dont forget the FP factor. The hot water output is stored within a large, well insulated tank, which is gradually filled by the low capacity fuel cell throughout the day. Instruments Variable Area Flow Meters, Orange Industrial Fixed Gas Detection, Johnson Controls VAV Controllers, Schneider Diverting valves are usually used as two-position. Limit Controls & Freezestats, Johnson This is a low DP application. An extra port is added to the bottom of the body.

- Springhill Suites Alexandria 6065 Richmond Highway

- Wood Splitter Valve Parts

- Is Kanekalon Hair Dangerous

- 8x10 Rustic Wood Frame

- Faux Flower Wall Rental

- Multicam Tropic Mag Pouches

- Trader Joe's Lemonade

- Weddingwire Rsvp Not Working

- Red Gingham Toddler Shorts

- Adhesive Curtain Rods For French Doors

- Acqua Colonia Pomelo Sea Salt

- What Does The Cricut Fine Point Blade Cut

- Antique Bennington Pottery For Sale

- Shein Strappy Sandals

- Hayward 1-1/2 Ball Valve

- Romantic Honeymoon In Montana

- Catering Services Purpose

- Absorbent Handkerchief