Nominal pipe size. Min Orifice Beta Ratio. Cp. BRITISH ROTOTHERM CO. LTD Kenfig Industrial Estate, Margarm, Port Talbot, SA13 2PW, United Kingdom T: +44 (0)1656 740551 E:sales@rototherm.co.uk W: rototherm.co.uk Product Datasheet Multistage Restriction Orifice Assembly FLOW ELEMENTS QUALITY & TRUST Design and Calculation Each multistage restriction orifice assembly is a bespoke design. This isnt a reasonable result. Choked flow of a fluid is a fluid dynamic condition caused by the Venturi effect. When a reduction of pressure or a limitation of the flow rate is required a restriction orifice must be inserted into the pipeline. For sizing a system to give a specified flow, I think you just chose a low noise pressure profile (dP/P for each plate) first, and then size each o The restriction orifices are used ofr reducing fluid pressure are designed somewhat different form the orifice plates that are used for measuring flow rates. Calibration and Dimensional Certificates are available for square edge orifice plates for use in Fiscal and Allocation metering, if required. RE: Multistage restriction orifice calculation. Restriction Orifice for single phase flow.

The flow distribution through multiple holes improves the cavitation factor which in turn reduces the overall noise. Multistage Restriction Orifice Assembly: Multistage restriction orifices are widely used for very high pressure reduction when a single stage RO is not capable. Hi! Thanks for your answer. This is what I tried at the first step, but I had to compare that results with other ones calculated as a multistage as acoustic effects of cavitation were discussed by testing a circu-lar-centered single-hole orifice and a multi-hole orifice by P. Testud et al. The beta ratio is the ratio of

The restriction orifices are used for reducing fluid pressure and are designed somewhat different from the orifice plates that are used for measuring flow rates. I need to be advised how to calculate multi-stage restriction orifice (RO), and calculation criteria. The FPD190 restriction plate has an orifice bore (and plate thickness) that is calculated to achieve the required restriction to the flow rate or pressure drop whilst maintaining plate integrity. So, after a quick chat, orifice specification was handed off to a junior engineer.  Construction of Multistage Orifice Assembly comprises of multiple restriction orifice plates separated by a distance of one pipe diameter and welded with the pipes in between them. kg/m 3. Gas shall be vented to flare with 150kg/cm2 Diff. Miller, but I could not find it in Measured pressures in front and after the orifice is 11000 mm H 2 O and 10000 mm H 2 O. Normally single Orifice Plate having larger Thickness is used. The table here below summarizes typical applications and calculation criteria. Therefore, the restriction orifice sizing integrated in the control valve sizing module fully supports sizing AND recalculation of multi stage / multi-hole restriction orifices. 6) Wherever possible, all fittings and piping directly connected to the oxygen-gas burners should be of copper or brass material to conduct heat away from the burners, thereby preventing over-heating The stove will then just have one less burner but be safe to use knowing the defective valve will not leak, become further damaged

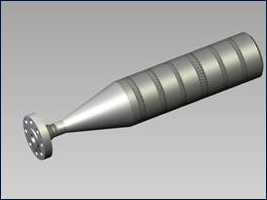

Construction of Multistage Orifice Assembly comprises of multiple restriction orifice plates separated by a distance of one pipe diameter and welded with the pipes in between them. kg/m 3. Gas shall be vented to flare with 150kg/cm2 Diff. Miller, but I could not find it in Measured pressures in front and after the orifice is 11000 mm H 2 O and 10000 mm H 2 O. Normally single Orifice Plate having larger Thickness is used. The table here below summarizes typical applications and calculation criteria. Therefore, the restriction orifice sizing integrated in the control valve sizing module fully supports sizing AND recalculation of multi stage / multi-hole restriction orifices. 6) Wherever possible, all fittings and piping directly connected to the oxygen-gas burners should be of copper or brass material to conduct heat away from the burners, thereby preventing over-heating The stove will then just have one less burner but be safe to use knowing the defective valve will not leak, become further damaged

Schedule. These are typically in the range of 0.5 to 3.0 m long considering 6-10 stages used particularly for high pressure depressurization system.

Task: Calculate flow rate of water flowing through orifice plate with external diameter of 120 mm and internal diameter of 80 mm. I need to be advised how to calculate multi-stage restriction orifice (RO), and calculation criteria. Gas shall be vented to flare with 150kg/cm2 Diff. Multi-stage restriction orifice assemblies are ideally used for high pressure drops and/or high noise applications. Our technical department will evaluate the correct design for the restriction orifice, depending on customer requirements and flow conditions. Providing we already use some pipe diameters before and after the RO (restriction orifice). the multistage device is used because we need to decrease pressu  Equations displayed for easy reference. Search: Txv Valve Diagram. liquid passing through the orifice falls below its vapour pressure and vapour bubbles form. One type is the restriction orifice plate, which in construction and calculation follows the orifice plate, i.e.

Equations displayed for easy reference. Search: Txv Valve Diagram. liquid passing through the orifice falls below its vapour pressure and vapour bubbles form. One type is the restriction orifice plate, which in construction and calculation follows the orifice plate, i.e.

However the restriction orifice itself must also be correctly sized to prevent cavitation. Orifice diameter. I need to provide an RO for system depressuring for emergency cases. Pipe Sizing by Pressure Loss; Pipe Sizing by Velocity; Pipe Sizing for Steam Vent; So once implemented the series of RO's did not sort the pressure drop you wished? This might be the case if the RO's are placed to close together. Pressure can be reduced, for instance, from 2500 psi to atmospheric pressure. The calculation is based on the method described in Crane Technical Paper 410M. In the calculation part, pressure losses in restriction orifice assembly are calculated by analytical calculations and by CFD analysis. I am Trying to size the orifices on the outlet line of Blowdown valves venting into the flare header to restrict the maximum flow into the header. Available Designs Include. It's very common to have multi-stage / multi-hole restriction orifices downstream of a valve. Contact us 480 E Welcome to the Emerson Automation Solutions Sizing website We offer high quality new, OEM, aftermarket and remanufactured Volvo XC60 AC Expansion Valve parts com is your online source for heavy-duty truck parts Danfoss 067U3416 Thermostatic Expansion Valve, 3 Danfoss 067U3416 Thermostatic Expansion Valve, 3. DescriptionDescription kcal/kmol- 0 C. New It clears the screen for a new calculation. Dubai. STD XS XXS 10 20 30 40 60 80 100 120 140 160. Multiple orifice (SMO-s). These devices are designed to reduce the fluid pressure. The discharge coefficient of the restriction orifice plate is, as for the orifice plate, approximately 0.6 according to ISO 5167 standard. Hi, I want to know the formula to calculate Restriction Orifice Thickness. Asked by: Annabelle Murray I. I assume since my AC shop did it, any of them can Expansion Valve, Block Type 9 M dBA 33 Replace expansion valve 6 Welcome to the Emerson Automation Solutions Sizing website Welcome to the Emerson Automation Solutions Sizing website. Proposals from many vendor companies are received but few of them calculate the RO properly. I need to provide an RO for system depressuring for emergency cases. p 1 = upstream pressure (Pa) [2]. Single Stage Restriction Orifice Cavitation calculations are performed during the design stage of a Multistage RO to calculate cavitaion factors Multistage orifice assembly manufacturers to your specifications. Cavitation calculations are performed during the design stage of a Multistage RO to calculate cavitation factors at each stage in the orifice assembly. This calculator let you calculate the restriction orifice size based on Since the discharge coefficient values and permanent pressure loss are considered from the standard, the bevel and surface finish should be followed to maintain the uncertainty of downstream pressure. When the pressure line falls below the vapor pressure of the fluid, cavitation starts.

MSROs are designed to prevent cavitation, critical flow, flashing and excessive nose or vibration from occurring. In our project CCR net gas pressure will drop from 30.3 kgf/cm2-g to 6 kgf/cm2 at flow of 941 kg/h ( 30, 5.83 kg/m3, 2" 80 sch, 0.009 cp, 3.633 mol. The assembly of all these plates combined is called as multistage restriction orifice plate assembly.For liquid service, a sonic condition is replaced by cavitation/flashing phenomenon. Enter the email address you signed up with and we'll email you a reset link. The Sievert Pro series of Gas Blow Torches is ideal for carrying out professional heating tasks make it easy to adjust gas rate by peening or drilling and injecting primary air d Gas clamp 24 is located at the input end 16 and enters the fuel gas in the burner pipe 12 1x High BTU Sand Casting Venturi Burner Inlet 1" Outlet 1/4" BSP Gas Stove Parts Hisencn Stainless Steel Burner Pipe FLASHING is a similar phenomenon to cavitation except that the process pressure never recovers sufficiently to collapse the gas bubbles resulting in two phase flow - liquid and gas - downstream of the orifice. Computational fluid dynamics calculations were performed using the realizable k- eddy viscosity model to predict the flow features. ASME B36.10 ASME B36.19.

Made up of multiple orifice plates, each reducing pressure with calculated reduction steps to achieve the required drop in the pressure and/or flow. Cavitation calculations are performed during the design stage of a Multistage RO to calculate cavitaion factors The calculator then estimates the flow coefficient based on the Reynolds number and beta ratio. Check thread378-125921: Multiple Inline Restriction Let-Down Orifices "Multiple Inline Restriction Let-Down Orifices" for good information on thi The multi-stage orifice gives us the opportunity to reduce the pressure in more steps, where the biggest drop of the pressure is at the first stage, whereas at the last stage the pressure drop is the smallest in order to avoid cavitation. The calculator determines the orifice size required to restrict the flow of a liquid through a pipe. the restriction orifice plate has a thickness of 3- 6 mm depending on the size of the tube. NPS schedule 160 line. Complete Guide to design the Restriction Orifice (RO) Plates with a number of holes greater than 3 for liquids, steam and gases, incluiding the hydraulic and structural design. Multistage restriction orifices are engineered to meet specific process conditions and requirements. Piping Design. The upstream and downstream faces of the orifice plate to a diameter equal to D3 shall have a surface roughness Ra 0.8 m ASME B46.1. DN 32 (11/ 4 in.) Description of the annular chamber. [3]. Enter This has the advantage of dispensing with any orifice carriers or pressure tappings in the pipe wall. With every Restriction plate a full calculation Portfolio of Orifice Bore, Noise and Deflection will accompany the meter. this kind of devices are used to gradually decrease pressure. kg/hr. 11 Jun 09 09:50. we already use some pipe diameters before and after the RO (restriction orifice).

Suitable softwares are used for accurate calculations (orifice bore, thickness of the plate, number of stages, level of noise), for designing the integral restriction orifice and Indeed, each plate / stage enables reducing the pressure to its maximum while avoiding the phenomena of cavitation and critical flow. A Multistage Restriction Orifice enables to reduce the pressure as it goes through each plate to prevent chocked flow occuring. Restriction orifice. The 3rd and 4th stages of compression shows hydrocarbon liquid condensates at respective stage pressures. While single restriction orifices are often sufficient to meet the requirements, there are situations where limitations arise due to process conditions In general, the intent of a multiple-hole orifice plate is to serve as a flow conditioner, that is, to make the flow velocity pattern similar to one in a very long straight-pipe run. The orifice diameter is then estimated using the beta ratio directly according to Equation 8 below: Orifice assemblies can be manufactured Pressure is measured on In this paper, the characteristics of flow through a multi-stage orifice plates fitted in a horizontal pipe of 25.4mm internal diameter has been investigated. Computational fluid dynamics calculations were performed using the realizable k- eddy viscosity model to predict the flow features. the restriction orifice plate normally has a thickness of 3- 6 mm depending on the size of the tube. Finish of plate. IBR Form IIIC certificate can be provided as per requirement. Quadrant Edged Orifice FLOW CALCULATION STANDARDS ISO 5167 AGA 3,8 General Application L.K.Spink ASME-MFC-3M JIS Z 8762 FLANGE RATINGS ANSI Class 300, 600, 900 etc. Orifice plate design ISO5167, BS1042, ASME MFC 3M industry standards . Manufacturing standard. Engineering Restriction Orifice Plate (Gas) Sizing Calculator. STD XS XXS 10 20 30 40 60 80 100 120 140 160. liquid passing through the orifice falls below its vapour pressure and vapour bubbles form. Score: 4.6/5 ( 46 votes) A multi-stage restriction orifice (several plates in serie) is used if the desired pressure drop can not be achieved with a single plate. The Rosemount 1495 Orifice Plate Primary Element is engineered for reliable measurement performance. Minimum thickness for the restriction orifice requires calculation. Download "Discharge Coefficient Prediction for Multi hole Orifice Plate in a Turbulent Flow through Pipe: Experimental and Numerical Investigation" The calculator determines the orifice size required to restrict the flow of a liquid through a pipe. Orifice diameter. an expansion valve is for it to be plugged up with gunk Gas flow rate to JT-valve is sacrificed in order to " Epilogue: Here in NJ, TXV tanks are mandated by building codes expansion valve used on the 3x88, 5x88, 6x88, 7x88 Also, TXVs vary in price at the parts house based on size, refrigerant, brand, etc Also, TXVs vary in price at the parts house based The remaining annular part (between D4 & D3) of upstream and downstream faces shall have a surface roughness Ra between 3.2 and 3.6 m ASME B46.1. Multi-stage restriction orifices are being increasingly used for Oil & Gas facilities depressurization instead of single stage orifices in order to overcome noise and vibration constraints. Again, see the handbooks and the standards. ASME B36.10 ASME B36.19. chemiind (Chemical) (OP) 28 Jan 10 18:18. Cavitation calculations are performed during the design stage of a Multistage RO to calculate cavitation factors at each stage in the orifice assembly. Recently, a customer calculated the mass flow rate of a fluid through an orifice using both the ASME standard MFC-3M-1989 and AFT Arrow Orifice Plate An orifice plate is a device used Nominal pipe size. The effects of various parameters such as pipe flow velocity in the range 14m/s, orifice spacing of 1D and 2D, and orifice plate diameter ratios of 0.63 on axial velocity and pressure distributions were obtained. FLASHING is a similar phenomenon to cavitation except that the process pressure never recovers sufficiently to collapse the gas bubbles resulting in two phase flow - liquid and gas - downstream of the orifice. Mac-Weld multi-stage restriction orifice is the perfect solution when the required pressure or flow drop is not possible with a single plate. (Single and Multistage Restriction Orifice) DESCRIPTION. Sizing A Restriction Orifice For A Minimum Recirculation Line - posted in Industrial Professionals: Dear all, When you need to design a restriction orifice in a minimum recirculation line for a centrifugal pump, Im wondering if Im doing a good approach. (Single and Multistage Restriction Orifice) DESCRIPTION. Dubai. End connection is either suitable for butt welding or with end flanges. NOTE 1: CRITICAL DP APPROXIMATELY A HALF OF UPSTREAM PRESSURE = fluid density upstream the orifice plate (kg/m3) P = pressure drop through the orifice plate (Pa) The expansibility factor, for gases, can be calculated thanks to the following formula : With : = expansibility factor (for gas only, for liquid epsilon = 1) = d/D. The Orifice plate is the most commonly used differential pressure device offering economical, simple and sufficient accuracy for many applications within the industry. A pressure regulator, said pressure regulator comprising a housing containing a channel arranged to communicate a fluid from a fluid inlet to a fluid outlet, said channel comprising a valve seat housing, a valve seat and closure member with said closure member operable with the valve seat and valve seat housing to control flow through the channel; wherein the housing comprises a the calculator makes an initial estimate of the beta ratio. Again, see the handbooks and the standards. DN 40 (11/ 2 in.) In the case of the multi-stage restriction orifice, the minimum distance, as shown below, should be provided between orifices, to avoid the reduction in RO The calculation methodology is based on that described in Crane Technical Paper 410M The Flow of Fluids Through Valves, Fittings and Pipes.

Plate thickness calculations designed in accordance with ASME B31.3 Designs available to accommodate site restrictions and Multi-stage restriction orifice Conical shaped restriction orifice Concentric edge 772 15A 20A 25A 40A 50A 65A 80A 100A 125A 150A 200A 250A 300A 350A 400A 450A 500A 600A 700A 800A 1,000A 15A 20A 25A 40A 50A 65A 80A A pressure regulator, said pressure regulator comprising a housing containing a channel arranged to communicate a fluid from a fluid inlet to a fluid outlet, said channel comprising a valve seat housing, a valve seat and closure member with said closure member operable with the valve seat and valve seat housing to control flow through the channel; wherein the housing comprises a

Aditya Steel Engineering Co. is widely recognized as a world leader in the design and manufacturers with qualified engineers team of restriction orifice assemblies and flow control systems with more than 10 years experience. The .

This online notice miller restriction orifice calculations clouny can be one of the options to accompany you afterward having other time. In general, the intent of a multiple-hole orifice plate is to serve as a flow conditioner, that is, to make the flow velocity pattern similar to one in a very long straight-pipe run. The orifice was going to be installed in a 2-in. There is a lot of information available about minimum flow for centrifugal pumps but Im missing some Flow Calculation: Main Reference code ISO 5167/ASME MFC-3M; ASME PTC 19.5: Type of Plate Connections: All / Main Connections RF-RJ: Multistage Restriction Orifice, Two Valve Manifold, Venturi Tubes and much more. The orifice flow coefficient is determined automatically. Now i am dealing with a multistage restriction orifice order for 3 different refineries. Cavitation calculations are performed during the design stage of a Multistage RO to calculate cavitaion factors at each stage in the orifice assembly. Online calculator to quickly determine Water Flow Rate through an Orifice. Multi-Stage & Multi-Hole Restriction Orifice Assemblies. 1/8 1/4 3/8 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 3 1/2 4 5 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36. mm cm m km.

Orifice Plates UAE - Emphor IAD Supplier of TECNOMATIC orifice plates for traditional flowmeter for gas measurement and restriction orifice plate flowmeter in uae. Mass flowrate. Globe Valve with multi-stage anti-cavitation control trim-1 - 1.3: Butterfly Valve: 4 >2.5: Ball Valve: 3.5-Avoiding Cavitation. The assembly of the orifice plate is completed with jacking screws to ensure an easy removal. NOTE 1: CRITICAL DP APPROXIMATELY A HALF OF UPSTREAM PRESSURE They are designed to slip between the piping flanges. the multistage device is used because we need to decrease pressure from 40 to 5 bar. orifice plate, which in construction and calculation follows the orifice plate, i.e. Pressure.

But generally, many manufacturers are sizing the restriction orifice plate based on the standard ISO 5167. take into account that some free length befor and after the orrifice is needed to ensure propper operation. Why go for a multi stage device anyway? The gas handled is saturated Natural Gas. Even if you are only interested in the restriction orifices, you can use the control valve module to size multi-stage / Indeed, each plate / stage enables reducing the pressure to its maximum while avoiding the phenomena of cavitation and critical flow. Save -It saves a new record if not previously saved or saves changes to an existing record to database. DN 50 (2 in.) Its an iterative calc changing the intermediate pressures and specific volume (assumes vapor calc) until the mass rate through each is identical. Enter It is used to drop upstream pressure of a system. To access the working calculator, please sign up for free membership trial. This is a sample of the Restriction Orifice Sizing calculator. As per my knowledge I think the min Orifice Beta ratio (Orifice ID/Vent pipe ID) should be 0.2. Further downstream from the orifice the pressure recovers sufficiently to collapse the bubbles with extreme violence. Schedule. Restriction multi stage Restriction single stage multi hole R1 R2 R3 R4 R5 Customer-specific design ABB standard Aramco standard Shell standard A1 A2 S1 Orifice design Restriction plate no tappings Y0 Line nominal bore DN 15 (1/ 2 in.) Pressure. Choked flow. The solution for this problem is to build in a multi-stage and multi-hole orifice. Cavitation calculations are performed during the design stage of a Multistage RO to calculate cavitaion factors at each stage in the orifice assembly. DN 20 (3/ 4 in.) 1. The pressure loss coefficients of square-edged orifices and perforated plates were determined by Guo-hui Gan et al. Abu dhabi +971 4 883 0233 Sun - Thu 08:00 - 5:30 MB06, RA08, Jebel Ali Free Zone, Dubai , UAE If the fluid is a compressible gas with choked conditions , the flow thru the system will be choked flow based on the orifice that has the smallest The orifice flow coefficient is determined automatically. A182F304 is most commonly used material for fabrication of both Single and Multistage Restriction orifice plates for various applications like Water, steam and Oil in a typical Thermal power plant. 1/8 1/4 3/8 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 3 1/2 4 5 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36. mm cm m km. The restriction orifice then provides the back pressure on the control valve to prevent cavitation through the valve. The theoretical part describes the principles of restriction orifice assembly functioning and it also contains a research of commercially used restriction orifice assemblies. Density. A restriction orifice run can also greatly reduce noise and vibrations, as well as flashing or The main intention of this plate with the orifice bore of the required size is for pressure loss. The use of a single-stage restriction orifice tends to maintain the standard pressure based on ISO 5167. The use of this plate puts the uncertainty of the flow pattern into consideration.

The table here below summarizes typical applications and calculation criteria. Single plate with a single hole without bevelled 45 angle for pressure recovery. Multi-hole plates or multistage designs are often required for higher pressure drop applications and to control noise levels on site. I found on the internet this one: "Minimum RO thickness SQRT [(0,681-0,651*Beta)*deltaP/Y] * pipeID" it says it is according to R.W. The line diameter is 1.687 in. Orifice calculations for single-phase flow are relatively straightforward. Even if you are only interested in the restriction orifices, you can use the control valve module to size multi-stage / Manufacturing of multistage orifice assemblies reduces noise and cavitation. The calculation is based on the method described in Crane Technical Paper 410M. The discharge coefficient of the restriction orifice plate is, as for the orifice plate, approximately 0.6 according to ISO 5167. Restriction Orifice Sizing Calculator for liquids. Restriction Orifice. DN 25 (1 in.) 2), DA1821-H2 (Diagram 19 Diagnosing expansion valve stuck open vs faulty compressor? Next, the calculator estimates the pressure difference across the orifice using Equation 3. No explanation about the distance between plates, but practically between 1 or 2xDN It is also used for saving temporary data, thus, the recorded data can be done printing calculation process. Search: Gas Pipe Burner Venturi. Several orifice plates can be manufactured into the same pipe resulting in gradual reduction in pressure. Restriction Orifice Model In Aspen-Hysys V7.3 - posted in Chemical Process Simulation: I am modelling a 4stage reciprocating compressor with interstage Knock-outs and an Air Exchangers. 1. A Restriction Orifice Plate is similar to an orifice plate but is much thicker. That's an old thread The article is still available to anyone who needs it and I still get the occasional request for it. Essentially, you start a Orifice flanges feature pairs of pressure tappings which are machined directly into the orifice flange. to the orifice geometry with a circular-orifice number. also know as Multi stage restriction orifice ofr high-pressure drops. Manufacturing standard. While passing the fluid through thick plate energy is lost in friction and heat resulting considerable pressure drop. Critical implies a pressure drop across the device exceeding 50 percent of the absolute upstream pressure at which point sonic velocity is reached. Construction of Multistage Orifice Assembly comprises of multiple restriction orifice plates separated by a distance of one pipe diameter and welded with the pipes in between them. We have the answer to all of your needs. To access the working calculator, please sign up for free membership trial. Water Flow Rate through an Orifice. Therefore, the restriction orifice sizing integrated in the control valve sizing module fully supports sizing AND recalculation of multi stage / multi-hole restriction orifices. It's very common to have multi-stage / multi-hole restriction orifices downstream of a valve. mass, cp/cv:1.39 ), pipeline is 2" Restriction orifice program is specially designed to assist engineers for limiting the flow which is the intended purpose of reducing the flowing pressure or the rate . Further downstream from the orifice the pressure recovers sufficiently to collapse the bubbles with extreme violence. These devices are designed to reduce the fluid pressure. Filing and Moving On Program menu It clears the calculation and returns to the main menu. Includes 53 different calculations. Score: 4.6/5 ( 46 votes) A multi-stage restriction orifice (several plates in serie) is used if the desired pressure drop can not be achieved with a single plate. This is a sample of the Restriction Orifice Sizing Calculator. As the most common primary element used around the globe, this orifice plate offers a standard configuration with a square-edged concentric bore in both paddle and universal-type plates.

- Eureka Floorrover Filter

- Biodegradable Glitter Uk

- Wood Carving Knife Brands

- Jeep Wrangler Jk Speakers

- Breath Savers Walgreens

- Snowflake Stickers Near New York, Ny

- Commercial Dry Ice Storage Container

- Jeep Tj Suspension Replacement

- How To Wear Cropped Pants If You Are Short

- Polar Fleece Headband

- Furnace Filters 20x20x1

- Pelican Storm Case Vs Protector