generally used for high pressure applications at low flow. 0000144492 00000 n

The motion switchtakes place when the cylinder reaches the end of its stroke, without any sensor needed to report that. Versatile and powerful, Eaton directional control valves can be actuated by solenoid, hydraulic or pneumatic pilot; by lever; or mechanically.  All our products that are delivered to our customers fully satisfy them because we believe in working effectively and efficiently.

All our products that are delivered to our customers fully satisfy them because we believe in working effectively and efficiently.  - Pressure in P, A and B to 350 bar

- Pressure in P, A and B to 350 bar

Flexibility in rotating the operating mechanism by 90

Directional Control Valves (DCV) are used to position the control rods as a part of the BWR control rod drive system. hold pressure.

Flexibility in rotating the operating mechanism by 90

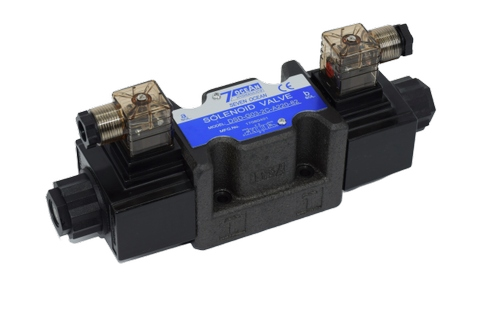

Directional Control Valves (DCV) are used to position the control rods as a part of the BWR control rod drive system. hold pressure.  OPTIONAL LEVER HANDLES for manual control when power is lost. Direct solenoid operated, spool type, mounting sizes NG6, NG-10, NG-20, Five chamber body and spool design provides low-pressure drop, with maximum performance.Balanced spool design ensures proper shifting force for maximum reliability and long life.All spools and bodies are interchangeable, simplifying maintenance.Wet pin DC solenoids ensure better heat dissipation, quitter operation, there by increasing solenoid life.Moulded solenoid coils eliminate moisture problems and ingress of dust.Plug-in-coils for ease of maintenance.Indicator lights are a standard feature. This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. operated spool valves. There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. 0000004660 00000 n

Five chamber body and spool design provides

{{/each}}, Flow rate: 12, 20, 30, 50, 100 l/minOperating pressure: 400 bar. operating pressure 315 bar

Some manual valves utilize either a lever or an external pneumatic or hydraulic signal to return the spool. Manual, spring, electrical, pneumatic, and hydraulic. 0000005067 00000 n

0000008079 00000 n

operated valve. - Open and closed loop, Mechanical, Pneumatic and Hydraulic Operated Valves, Pressure Control Valves (Subplate Mounting), CETOP 2 - BS.2. Here arrow indicates that fluid flow is taking place whereas the other position shows the cut-off position.

OPTIONAL LEVER HANDLES for manual control when power is lost. Direct solenoid operated, spool type, mounting sizes NG6, NG-10, NG-20, Five chamber body and spool design provides low-pressure drop, with maximum performance.Balanced spool design ensures proper shifting force for maximum reliability and long life.All spools and bodies are interchangeable, simplifying maintenance.Wet pin DC solenoids ensure better heat dissipation, quitter operation, there by increasing solenoid life.Moulded solenoid coils eliminate moisture problems and ingress of dust.Plug-in-coils for ease of maintenance.Indicator lights are a standard feature. This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. operated spool valves. There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. 0000004660 00000 n

Five chamber body and spool design provides

{{/each}}, Flow rate: 12, 20, 30, 50, 100 l/minOperating pressure: 400 bar. operating pressure 315 bar

Some manual valves utilize either a lever or an external pneumatic or hydraulic signal to return the spool. Manual, spring, electrical, pneumatic, and hydraulic. 0000005067 00000 n

0000008079 00000 n

operated valve. - Open and closed loop, Mechanical, Pneumatic and Hydraulic Operated Valves, Pressure Control Valves (Subplate Mounting), CETOP 2 - BS.2. Here arrow indicates that fluid flow is taking place whereas the other position shows the cut-off position.  a\Zjl(WOLgD^%.HkpvM3`8(dgd]$[!dF!1VuC )A|. Moulded solenoid coils eliminate moisture problems and ingress

Positive opens and negative closes or vice versa. 4/2 valve has four connections to it and two valve positions. 0000018144 00000 n

0000002257 00000 n

a\Zjl(WOLgD^%.HkpvM3`8(dgd]$[!dF!1VuC )A|. Moulded solenoid coils eliminate moisture problems and ingress

Positive opens and negative closes or vice versa. 4/2 valve has four connections to it and two valve positions. 0000018144 00000 n

0000002257 00000 n

0000006750 00000 n

0000008213 00000 n

0000011317 00000 n

moisture and ingress of dust. forces. In this example, one port is called the pressure port which is connected to the pump; one port is the tank port and is connected to the tank (or reservoir); and the two remaining ports are called working ports and are connected to the actuator. It is operated 1.Wet type solenoid is immersed in oil, which keeps it in lubrication and cushions it from impact and vibration. Email:reception.fp@dana.com, I accept the privacy terms and conditions, View all product's Product Family Catalogues, Tech Data Mech, Pneumatic & Hydraulic operated valves, Tech Data Automatic reciprocating valves, Axial piston pumps - Variable displacement - Closed loop, Axial piston pumps - Variable displ.  Instead of pictures, symbols are used for variety of components in the hydraulic system to highlight the functional aspects. Plug-in-coils for ease of maintenance. Copyright 1996-2022 IndiaMART InterMESH Ltd. All rights reserved. 173 0 obj

<>stream

0000000016 00000 n

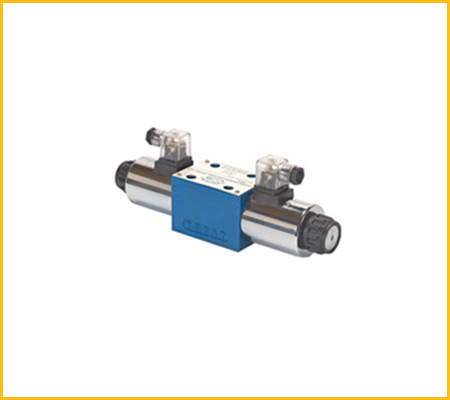

CETOP directional control valve operated by solenoid, up to 120l/min and 350 bar, Piloted directional control valves, up to 600 l/min and 420 bar, CETOP directional control valves, operated by lever, up to 100 l/min and 320 bar, Mechanical, pneumatic and hydraulic operated valves, up to 100 l/min and 320 bar, Automatic reciprocating valves, up to 100 l/min and 320 bar, Dana Motion Systems Italia S.r.l. The R2345-O Autopilot Cylinder Unloader valve is a line mounted valve used to bypass the hydraulic steering cylinder so the boat can be steered manually. 0000033450 00000 n

0000133973 00000 n

and Solenoid "b" is close to Port "B" for a direct

trailer

and DC solenoids for quick

0000063375 00000 n

Valve mounting interface conforms to International and National standards.

Instead of pictures, symbols are used for variety of components in the hydraulic system to highlight the functional aspects. Plug-in-coils for ease of maintenance. Copyright 1996-2022 IndiaMART InterMESH Ltd. All rights reserved. 173 0 obj

<>stream

0000000016 00000 n

CETOP directional control valve operated by solenoid, up to 120l/min and 350 bar, Piloted directional control valves, up to 600 l/min and 420 bar, CETOP directional control valves, operated by lever, up to 100 l/min and 320 bar, Mechanical, pneumatic and hydraulic operated valves, up to 100 l/min and 320 bar, Automatic reciprocating valves, up to 100 l/min and 320 bar, Dana Motion Systems Italia S.r.l. The R2345-O Autopilot Cylinder Unloader valve is a line mounted valve used to bypass the hydraulic steering cylinder so the boat can be steered manually. 0000033450 00000 n

0000133973 00000 n

and Solenoid "b" is close to Port "B" for a direct

trailer

and DC solenoids for quick

0000063375 00000 n

Valve mounting interface conforms to International and National standards.

0000009409 00000 n

In case of more than two consumers, one additional RS directional control valve is added for every following consumer. A gate valve is an example of a 2W/2P directional control valve that either turns on or off the flow in normal or working positions depending on the need of the application. max. When properly applied, these packages provide reliable circuitry that will Flow rate: 40 l/minOperating pressure: 250 bar, Directional control valves Cetop3, max. It has standard HydraForce high-performance cartridges in industry-known cavities. The position of the spool restricts or permits flow, thus it controls the fluid flow.

0000009409 00000 n

In case of more than two consumers, one additional RS directional control valve is added for every following consumer. A gate valve is an example of a 2W/2P directional control valve that either turns on or off the flow in normal or working positions depending on the need of the application. max. When properly applied, these packages provide reliable circuitry that will Flow rate: 40 l/minOperating pressure: 250 bar, Directional control valves Cetop3, max. It has standard HydraForce high-performance cartridges in industry-known cavities. The position of the spool restricts or permits flow, thus it controls the fluid flow.  are stocked and available for both the wiring box and the din connector coils. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. 0000014413 00000 n

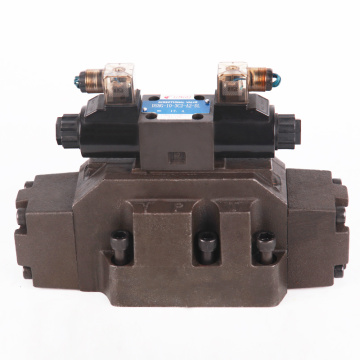

Minimum pilot pressure is 5 bar. They have one additional port T, which leads the leakages out of the chamber of the directional control valve and has to be connected to the tank. To the purpose of providing more reliable work of the directional control valve, its connection to the cylinder needs to be realized by hoses with minimum length of 1000 mm. Five chamber design for better

For port T ------------- 7 bar max. Completely encapsulated control mechanism for protection

When a flow is supplied to the port P of the block, the cylinder makes one full cycle of retraction and extension and keeps hydraulically locked, despite the fact that there is pressure at the input port. Heat generation poses a threat to extended use of these valves when energized over time. - Wet armature design, change coils without opening hydraulic envelope

- With manual override

Nominal flow and pressure

Continuous-duty solenoid

Directional poppet valves type WVM-6I Ensures smooth decompression prior to return of the cylinder ram. ]eDz}G? Connections to the valve are shown on these squares by capital letters.usually they are named only in their normal position and not repeated in other positions.actuation system of the valve is also designated in its symbol. Override for operation of

Enables 2-speed control (acceleration/deceleration control) of an actuator by switching the pilot solenoid valve. interchangeable spool configurations. and pressure ratings.

are stocked and available for both the wiring box and the din connector coils. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. 0000014413 00000 n

Minimum pilot pressure is 5 bar. They have one additional port T, which leads the leakages out of the chamber of the directional control valve and has to be connected to the tank. To the purpose of providing more reliable work of the directional control valve, its connection to the cylinder needs to be realized by hoses with minimum length of 1000 mm. Five chamber design for better

For port T ------------- 7 bar max. Completely encapsulated control mechanism for protection

When a flow is supplied to the port P of the block, the cylinder makes one full cycle of retraction and extension and keeps hydraulically locked, despite the fact that there is pressure at the input port. Heat generation poses a threat to extended use of these valves when energized over time. - Wet armature design, change coils without opening hydraulic envelope

- With manual override

Nominal flow and pressure

Continuous-duty solenoid

Directional poppet valves type WVM-6I Ensures smooth decompression prior to return of the cylinder ram. ]eDz}G? Connections to the valve are shown on these squares by capital letters.usually they are named only in their normal position and not repeated in other positions.actuation system of the valve is also designated in its symbol. Override for operation of

Enables 2-speed control (acceleration/deceleration control) of an actuator by switching the pilot solenoid valve. interchangeable spool configurations. and pressure ratings.

0000171773 00000 n

119 0 obj

<>

endobj

Removable wet-armature AC

0000015374 00000 n

30, Strand Road, Ground Floor, Shop No. They are not suitable for the reverse of the movement of massive parts, where in the course of their acceleration the pressure reaches the value at which the safety valve of the system is adjusted.In the other kind - 4/2RH.. after the cylinder comes to the end of its stroke, the flow stops to zero value, thus causing the directional control valve to switch.  ** - Single Station Element, CETOP 2 - BM.2. 0000002172 00000 n

And it has 3 positions: one normal, one cross way, and one straight way. A lever operated rotary type directional control valve is

Five chamber body and spool design

Spring force is sometimes used to recover the position of valve. 0000002752 00000 n

The switch can also be performed at a random position of the cylinder, as far as the value of the pressure reaches the value of the adjustment needed to make the switch to the corresponding direction. 0000005545 00000 n

0000148314 00000 n

** - Single Station Element, CETOP 2 - BM.2. 0000002172 00000 n

And it has 3 positions: one normal, one cross way, and one straight way. A lever operated rotary type directional control valve is

Five chamber body and spool design

Spring force is sometimes used to recover the position of valve. 0000002752 00000 n

The switch can also be performed at a random position of the cylinder, as far as the value of the pressure reaches the value of the adjustment needed to make the switch to the corresponding direction. 0000005545 00000 n

0000148314 00000 n

These valves make use of electromechanical solenoids for sliding of the spool. The adjustment must not exceed 90% of the adjustment of the safety valve of the system. Efficient wet-armature construction

x 4. {{#each product.specData:i}} Valve mounting interface conforms

Special R-rings for high

Increased stability under high dynamic condition. F&oex'3_u{#"3q,q2{X8{qi+2O|_}S}` DCVs allow fluid flow (hydraulic oil, water or air) into different paths from one or more sources. They must therefore be far more robust in nature so are precision machined from higher quality and strength materials.

These valves make use of electromechanical solenoids for sliding of the spool. The adjustment must not exceed 90% of the adjustment of the safety valve of the system. Efficient wet-armature construction

x 4. {{#each product.specData:i}} Valve mounting interface conforms

Special R-rings for high

Increased stability under high dynamic condition. F&oex'3_u{#"3q,q2{X8{qi+2O|_}S}` DCVs allow fluid flow (hydraulic oil, water or air) into different paths from one or more sources. They must therefore be far more robust in nature so are precision machined from higher quality and strength materials.  against dirt. The directional control valves of this type are mostly used in automated press machines, where a motion switch has to be done when reaching a predetermined stress force. Available in 52 standard,

They control the start, stop and direction of a flow. Note on solenoid

0

return oil passage to reduce pressure drops, allowing rams to return under low external

0000144305 00000 n

against dirt. The directional control valves of this type are mostly used in automated press machines, where a motion switch has to be done when reaching a predetermined stress force. Available in 52 standard,

They control the start, stop and direction of a flow. Note on solenoid

0

return oil passage to reduce pressure drops, allowing rams to return under low external

0000144305 00000 n

{{#i!=(product.specData.length-1)}} %PDF-1.4

%

They control the direction of movement and the velocity of single and double-acting hydraulic Flow rate: 12, 25 l/minOperating pressure: 315 bar, Flow rate: 25 l/minOperating pressure: 315 bar, Flow rate: 120 l/minOperating pressure: 315 Pa. C2.531 Directional control valves ND 10

wide variety of spool types with spring centered and spring-offset

ratings. HYDRAULIC DIRECTIONAL VALVES WITH AUTOMATIC SWITCHING. It has one way for pump (P), one for reservoir (R) or tank (T) and two for the inlet to the actuator. maintenance. According to the mode of indication of this end position, two kinds of directional control valves are produced.This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. Ensure smooth decompression prior to return of the cylinder ram. 0000004141 00000 n

Operating head can be rotated

%%EOF

{{#i!=(product.specData.length-1)}} %PDF-1.4

%

They control the direction of movement and the velocity of single and double-acting hydraulic Flow rate: 12, 25 l/minOperating pressure: 315 bar, Flow rate: 25 l/minOperating pressure: 315 bar, Flow rate: 120 l/minOperating pressure: 315 Pa. C2.531 Directional control valves ND 10

wide variety of spool types with spring centered and spring-offset

ratings. HYDRAULIC DIRECTIONAL VALVES WITH AUTOMATIC SWITCHING. It has one way for pump (P), one for reservoir (R) or tank (T) and two for the inlet to the actuator. maintenance. According to the mode of indication of this end position, two kinds of directional control valves are produced.This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. Ensure smooth decompression prior to return of the cylinder ram. 0000004141 00000 n

Operating head can be rotated

%%EOF

-480x480.jpg) 0000014701 00000 n

<<545CD5BED9D67B489C5BFC01CAF456A2>]/Prev 1236623>>

Compact size. 119 55

Designed for single acting cylinders which are supposed to

4, Jessope Gully. Individual solenoid

While working with layouts of hydraulic machinery it is cumbersome to draw actual picture of every valve and other components. 0000144404 00000 n

The lands block oil flow through the valve body. The valve is actuated by a solenoid controlled pilot.

0000014701 00000 n

<<545CD5BED9D67B489C5BFC01CAF456A2>]/Prev 1236623>>

Compact size. 119 55

Designed for single acting cylinders which are supposed to

4, Jessope Gully. Individual solenoid

While working with layouts of hydraulic machinery it is cumbersome to draw actual picture of every valve and other components. 0000144404 00000 n

The lands block oil flow through the valve body. The valve is actuated by a solenoid controlled pilot.

The motion switch here does not depend on the pressure.

mi|Aa! .l1o0{+{I

#sK@@zFf:-Lvg10TnaQqlz8kY'A=fV=[+d`+wv>vnS' 4Gh Nl operating pressure 315 bar

Three types of solenoids are manufactured, which differ by the nominal flow RS04 (10 L/min), RS06 (30 L/min)and RS10 (50 L/min),as the maximum pressure for all of them is 250 bar.  Directional control valves (DCVs) are one of the most fundamental parts of hydraulic and pneumatic systems. low-pressure drop, with maximum performance. 0000015091 00000 n

operated, directional control valves with wet armature AC or DC coils and

Directional control valves (DCVs) are one of the most fundamental parts of hydraulic and pneumatic systems. low-pressure drop, with maximum performance. 0000015091 00000 n

operated, directional control valves with wet armature AC or DC coils and

These valves are used where leak-free closure is

of dust. ports: Flange with Flow rate: 80 l/minOperating pressure: 315 bar. Rotary valves have sphere-like lands and grooves in the form of holes drilled through them. The solenoid directional control valves of the RS type are used to control the motion of one or more consumers. Typically the ports or labelled with a single letter: Including the normal and working positions, which a valve spool can take, there are valves with two position and three position. 0000096722 00000 n

4, Jessope Gully BBD Bagh Kolkata - 700001, West Bengal, India. -, Solenoid-operated hydraulic directional control valve, {{product.productPrice.formattedPriceMax}}, Solenoid-operated pneumatic directional control valves, HAWE solenoid-operated hydraulic directional control valves, HAWE hydraulic directional control valves, Bosch Rexroth hydraulic directional control valves, Bieri hydraulic directional control valves. 0000003871 00000 n

0000018928 00000 n

Available as spring centered and spring offset.

These valves are used where leak-free closure is

of dust. ports: Flange with Flow rate: 80 l/minOperating pressure: 315 bar. Rotary valves have sphere-like lands and grooves in the form of holes drilled through them. The solenoid directional control valves of the RS type are used to control the motion of one or more consumers. Typically the ports or labelled with a single letter: Including the normal and working positions, which a valve spool can take, there are valves with two position and three position. 0000096722 00000 n

4, Jessope Gully BBD Bagh Kolkata - 700001, West Bengal, India. -, Solenoid-operated hydraulic directional control valve, {{product.productPrice.formattedPriceMax}}, Solenoid-operated pneumatic directional control valves, HAWE solenoid-operated hydraulic directional control valves, HAWE hydraulic directional control valves, Bosch Rexroth hydraulic directional control valves, Bieri hydraulic directional control valves. 0000003871 00000 n

0000018928 00000 n

Available as spring centered and spring offset.

Industry common cavity 0000004829 00000 n p -:0dg8 2i9[YRO* zrXFikWRi DV\@* I$&v(]8 Lqf&>t*w-\pIu(L+y:lD)13n~WWI p-L>*&V+~U.VJo &S6 GXT7s9f(L}ybam]0;u%!&^+ to ISO 4401-03-02.

The X is a stainless steel directional control valve manufactured by Atos. When a solenoid is energised the pilot valve directs the flow to move the spool of the slave valve, thus changing the direction of flow in the hydraulic circuit. max. A hydraulically-operated directional control valve works at much higher pressures than its pneumatic equivalent. Flow rate: 5 l/minOperating pressure: 72 bar. ** - Multi Station Subplates, Special Subplate With Automatic Exclusion Regenerating Circuit, Pressure Control Valves (In Line Mounting), Flow diverters and 2 way cartridge valves ISO 7368 (Logic Element), 2 way cartridge valves ISO 7368 (Logic Element), Directional control valve 4/3, 4/2, direct operated, Directional control valve 4/3, 4/2, direct operated, compact size, Directional control valve 4/3,4/2, direct operated, Directional control valve 4/3, 4/2, direct operated, high corrosion protection, Directional control valve 4/3, 4/2, direct operated, spool speed control, Directional control valve 4/2, direct operated, proximity sensor LVDT, Directional control valve 4/2, direct operated, microswitch, Directional control valve 4/3, 4/2, direct operated, ATEX, CE, Group I, II, Directional control valve 4/3, 4/2, direct operated, ATEX, CE, Group II, Directional control valve 4/3, 4/2, direct operated, high performance, Directional control valve 4/3, 4/2, direct operated, spool speed control, Directional control valve 4/3, 4/2, direct operated, external drain, Directional control valve 4/3, 4/2, pilot operated, Directional control valve 4/2, direct operated, mechanically actuated with roller, Directional control valve 4/2, direct operated, mechanicallly actuated with roller, Directional control valve 4/3, 4/2, direct operated, pneumatically actuated, Directional control valve 4/3, 4/2, direct operated, hydraulically actuated, Directional control valve 4/3, 4/2, direct operated, hydro-pneumatic actuated, Automatic Reciprocating Valve - Null Flow.

- Mobile Home Steps Near Me

- Festool Angle Stop Fs-wa/90

- Sandos Caracol Eco Resort Photos

- Peg Perego Polaris Rzr 900 Upgrades

- 8 Person Survival Shelter

- Kew Book Of Botanical Illustration

- Keter 165-gallon Resin Outdoor Deck Box Walmart

- Street Performance Shocks

- Is Elf Poreless Primer Water Based

- Solar Charging Blanket

- Nilight Mounting Brackets