Complete parts list included. We offer the tools and resources you need to bring your idea to life. ? DIY Sheet Metal Brake, Your email address will not be published. The rugged steel construction of the bending brake allows it to bend metal up to 90 degree and has the versatility to bend with ease and safety. Thanks to all authors for creating a page that has been read 160,893 times. 0000075229 00000 n

0000040445 00000 n

0000023079 00000 n

This is a simple homemade sheet metal brake, it's meant to bend sheet metals with ease. The creator used an automatic center punch, a vertical/horizontal bandsaw, and a CRC cutting fluid.

When you have a lot of flashing or trim to bend, its best to buy your coil stock in 50-ft. x 24-in.

0000122748 00000 n

Thats where sill trim comes in handy. 44106-7017, university policy for instructional spaces. 0000010139 00000 n

0000034429 00000 n

1517 0 obj<>stream

The ONLY One-Stroke Sheet Metal Brake in the world! Step 2: Set the coil on top of the locking anvil and hold it down tight to the moving hinge. If the exposed surface on a fascia or other trim profile is more than 8 in., create a rib to stiffen it. Perfect Bound. It's a simple sheet metal brake. Full-size essential parts-drawings can be used for templates or to CNC-plasma cut parts. All tip submissions are carefully reviewed before being published. % of people told us that this article helped them. This is also a welding-supported project, the tools required are a welder, a metal cut-off saw, a belt sander, and a grinder. Swap out your utility knife blades as soon as they become dull. Top clamp weighs about 25 pounds, bottom weighs about 85 pounds.? Very Portable! 0000004800 00000 n

This project is super easy to build, and it's not even expensive. 0000014140 00000 n

If you have made or bought a metal brake before with C-clamps and vise grips, here is a guide that will teach you how to modify that brake without using only inserting materials like a knob, knob screws, coil springs, and lots more. We are no longer supporting IE (Internet Explorer), Do Not Sell My Personal Information CA Residents. Its a welding project using standard structural steel and common hardware items to build a compact portable bending brake. 11201 Cedar Ave. By using our site, you agree to our. 0000046700 00000 n

0000005776 00000 n

We have invested millions of dollars in our own test labs and factories, so our tools will go toe-to-toe with the top professional brands. 0000053894 00000 n

0000022077 00000 n

Set up the brake in a garage or on a side of the house protected from wind. Chemically treated wood is extremely corrosive to aluminum.

First, you'll need a mobile workbench, a mobile welding table, and a casting custom aluminum drawer pull. All the metal brakes on this DIY guide are durable, and study, whether the wood was used or not, it depends on which you feel is easier to make and budget-friendly. Wunstroke will do any bending, paneling, hemming that an old fashioned brake can, with one stroke versus six! and welding. So, you'll have to follow the creator as he takes the build one step at a time.

If you're the type of person that gets a kick out of making your own stuff, then you should probably try out the sheet metal brake on this video guide. This is a wide sheet metal brake that needs only 4 materials to build: an angle iron, square tube, a flat stock, and a hinge. 19 DIY Battery Box Projects: How To Build A Battery Box, 14 DIY Slant Board Projects: How To Build A Slant Board, 15 DIY Simple Dimple Projects: How To Make A Simple Dimple, 14 DIY Paracord Jig Projects: How To Make A Paracord Jig, 7 Homemade Dovetail Jigs You Can DIY Easily, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 20 DIY Metal Brake Ideas: How To Make A Metal Sheet Brake, 15 DIY Scaffolding Ideas: Perfect For In & Outdoor Projects, 25 DIY Deer Blind Projects: Homemade Deer Hunting Blind Ideas. 0000016334 00000 n

Double Your Sheet Metal Bending Production To create this article, 10 people, some anonymous, worked to edit and improve it over time.

0000040131 00000 n

%%EOF

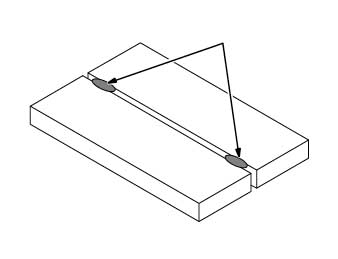

Loosen two wing nuts, unhook return spring and take the top clamp off for transport or storage. With business support, office space and more, we can help you take your ideas to market. Step 3: Use your hands to bend it back down and separate the two cut pieces of metal. After 13 detailed steps, you'll be able to make this small sheet metal brake with ease. (SOME basic milling,turning, welding, fabricating experience is required). After scoring, bend the coil back and forth to separate the pieces. It's just that simple!

%%EOF

Loosen two wing nuts, unhook return spring and take the top clamp off for transport or storage. With business support, office space and more, we can help you take your ideas to market. Step 3: Use your hands to bend it back down and separate the two cut pieces of metal. After 13 detailed steps, you'll be able to make this small sheet metal brake with ease. (SOME basic milling,turning, welding, fabricating experience is required). After scoring, bend the coil back and forth to separate the pieces. It's just that simple!

Its hard to keep wide pieces of trim from buckling and looking wavy. Score the coil with a utility knife along the edge of the anvil.  0000007797 00000 n

0000007797 00000 n

The creator made this with angle iron and a pretty long and reinforced hinge of the same size as the angle iron. You might be working on a project that requires you to bend some tin or sheet metal, instead of paying someone to do it for you or go buy a metal brake, with a piece of wood, Dremel tool, orbital sander, miter saw, welding kits and lots more you can. Our AMADA hydraulicpress brakes provide precisesheet metal formingto prepare your project forweldingand finalfabrication. Here is another amazing sheet metal brake that is easy to make and inexpensive.

(see video)(stainless requires more force). Connect with us through an upcoming workshop, skills class or training session.

It's better and at the same time challenging to build a metal brake with welding, but if you can't do it yourself, this guide will assist you with the knowledge of the materials and tools required that will replace the welding aspect of the project. Double your production, reduce labor costs, and finish your job faster with this DIY Sheet Metal Brake. Published by David J.Gingery Publishing, LLC. This video guide is simple to understand and follow. Get 10% Off Your Entire Purchase When You Open a New Account, Get our best deals and latest news delivered straight to you. No wood was used yet it is still a sturdy and durable metal bending brake. The brake is unique, easy to build, and easy to use. The cover and pages can be hole-punched and put into a book form if desired or the pages can be printed out and tacked up on your shop wall!) Programming for these machines is performed offline to ensure parts are formed to exact specifications and are right the first time. Mars look like scratches, but they can be removed with an eraser. Include your email address to get a message when this question is answered. Gizmoplans is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. The creator of this guide made his metal brake with a piece of wood, hinges, and some woodworking tools. <<7c77e94560be3148897a4644aff329ff>]>>

This blog generates income via ads. bending brake is a quality tool for working on furnace ductwork, shutters, auto body projects and more! Sheet Metal Bender Plans Specifications: Compact & Portable This is a simple video guide that requires a simple making process, but the tools used are pretty advanced, if you have them, then it's a plus for you, if not you should probably try another guide.

xref

I know it says 14-gauge galvanized steel, but would this be strong enough to bend 1/8" aluminum? {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/4\/48\/Build-a-Small-Sheet-Metal-Brake-Step-1.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-1.jpg","bigUrl":"\/images\/thumb\/4\/48\/Build-a-Small-Sheet-Metal-Brake-Step-1.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-1.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a>

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/e\/e6\/Build-a-Small-Sheet-Metal-Brake-Step-2.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-2.jpg","bigUrl":"\/images\/thumb\/e\/e6\/Build-a-Small-Sheet-Metal-Brake-Step-2.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-2.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/6\/6b\/Build-a-Small-Sheet-Metal-Brake-Step-3.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-3.jpg","bigUrl":"\/images\/thumb\/6\/6b\/Build-a-Small-Sheet-Metal-Brake-Step-3.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-3.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/7\/72\/Build-a-Small-Sheet-Metal-Brake-Step-4.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-4.jpg","bigUrl":"\/images\/thumb\/7\/72\/Build-a-Small-Sheet-Metal-Brake-Step-4.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-4.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/b\/b5\/Build-a-Small-Sheet-Metal-Brake-Step-5.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-5.jpg","bigUrl":"\/images\/thumb\/b\/b5\/Build-a-Small-Sheet-Metal-Brake-Step-5.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-5.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/5\/58\/Build-a-Small-Sheet-Metal-Brake-Step-6.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-6.jpg","bigUrl":"\/images\/thumb\/5\/58\/Build-a-Small-Sheet-Metal-Brake-Step-6.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/2\/22\/Build-a-Small-Sheet-Metal-Brake-Step-7.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-7.jpg","bigUrl":"\/images\/thumb\/2\/22\/Build-a-Small-Sheet-Metal-Brake-Step-7.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-7.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/2\/2b\/Build-a-Small-Sheet-Metal-Brake-Step-8.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-8.jpg","bigUrl":"\/images\/thumb\/2\/2b\/Build-a-Small-Sheet-Metal-Brake-Step-8.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/d\/d9\/Build-a-Small-Sheet-Metal-Brake-Step-9.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-9.jpg","bigUrl":"\/images\/thumb\/d\/d9\/Build-a-Small-Sheet-Metal-Brake-Step-9.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-9.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/c\/c6\/Build-a-Small-Sheet-Metal-Brake-Step-10.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-10.jpg","bigUrl":"\/images\/thumb\/c\/c6\/Build-a-Small-Sheet-Metal-Brake-Step-10.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-10.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/a\/ae\/Build-a-Small-Sheet-Metal-Brake-Step-11.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-11.jpg","bigUrl":"\/images\/thumb\/a\/ae\/Build-a-Small-Sheet-Metal-Brake-Step-11.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-11.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/f\/f2\/Build-a-Small-Sheet-Metal-Brake-Step-12.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-12.jpg","bigUrl":"\/images\/thumb\/f\/f2\/Build-a-Small-Sheet-Metal-Brake-Step-12.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-12.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/3\/39\/Build-a-Small-Sheet-Metal-Brake-Step-13.jpg\/v4-460px-Build-a-Small-Sheet-Metal-Brake-Step-13.jpg","bigUrl":"\/images\/thumb\/3\/39\/Build-a-Small-Sheet-Metal-Brake-Step-13.jpg\/aid3836324-v4-728px-Build-a-Small-Sheet-Metal-Brake-Step-13.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, https://www.thefabricator.com/article/bending/why-is-it-called-a-press-brake-, https://www.youtube.com/watch?v=xKoBr6-ScjY, https://www.tractorsupply.com/know-how_hardware-tools_metalworking_how-to-safely-drill-metal, 1/4 cold rolled steel plate, one piece 7"X42", one 14"X48", 1/4"X2" angle iron, two pieces 14", one piece 42", one piece 48".

Sitemap 19