Simply put, electroplating is the process of bonding one form of metal or compound alloy to another base metal in order to provide enhanced conductivity or protection; and while there are several types of electroplating, the rack and barrel methods are the most common. The more corrosion resistant the coating is, the longer the period in testing without showing signs of corrosion.

Neither of these two electroplating methods are better than the other. Consult'g, Train'g& Software, About/Contact-Privacy Policy-1995-2022 finishing.com, Pine Beach, New Jersey, USA, metal finishing service - Chemist - Manila, Philippines. Apart from the requirements, some applications that need rack plating service like copper alloys and nickel-silver, Steel, aluminum steel, Inconel and Monel, Stainless steel, etc. After loading the parts, you watch as the parts move about to get the plating solution coated on their surface. Vibratory plating, used for small or fragile parts.

These types of projects are much better suited for rack plating when possible. In addition, due to variable currents in the plating solution, uniformity of the plating layer is harder to achieve.

You can try salt spray test as this is the standardized test method to check corrosion resistance of coated samples.

As a result of the minimal contact, the finishing that will be achieved on the metal parts will be a high-quality coating. When any metal part is large and cannot pass through any other plating method, your best option is to plate it on a rack. We also use PLC controlled automatic rack lines which are capable of large production runs and weights up to 250 lbs.

Zinc can work in many cases if you find the right plater. Case ind point, A few years ago is saw a bright zinc plated dog leash chain that had a bright blue-clear chromate applied. Due to the low current requirement of barrel plating technique, the metal parts are exposed longer than necessary. We notice the surface finish of nickel plated parts being of a superior quality (mirror-like) than zinc plated. This surface finish is commonly used in circuit boards, automotive parts or the defense industry. This causes the parts to remain stationary upon immersion of the metal rack into the plating solution. This prevents damage to parts during processing and facilitates the processing of much larger parts that could not be barrel plated.

Some parts that have complex geometry which you must plate the contours can still get a uniform finishing through rack plating method.

Both barrel and rack plating are compatible with a wide variety of metal finishing technologies such as zinc, tin, copper and nickel, as well as precious metals such as gold and silver. During rack plating, parts are attached to you guessed it racks which are dipped into a plating solution and exposed to an electrical current. No matter how tempting it is to finish your project on time, you cant just use barrel plating without making sure that it can provide a perfect finish for the metal parts.

Or maybe the parts you need to plate are made of materials like copper, nickel or stainless steel.

Larger parts that have excessive weight or parts that can become entangled or easily nest together cannot be plated in a vibratory basket as they will not move in a uniform fashion. This will help to determine the plating thickness required for a part to be resistant to corrosion or repeated cycles of wear, for example.

Be it parts cleaning, rinsing, parts pickling or even sealing, all you need is one single vessel, and thats it! Selective plating is ideal for specific applications where functional plating is required for performance and/or cost savings with precious metal by reducing the surface area necessary to plate. Both methods are compatible with different finishing technologies.

Be it parts cleaning, rinsing, parts pickling or even sealing, all you need is one single vessel, and thats it! Selective plating is ideal for specific applications where functional plating is required for performance and/or cost savings with precious metal by reducing the surface area necessary to plate. Both methods are compatible with different finishing technologies.

If you are choked up with work or the pressure to deliver electroplated parts for item fabrication is making you stressed, barrel plating is the best thing that can happen to you at this point. Each of the items is purely on their own with little or no contact with other parts. In addition to the mechanical or functional properties which may be altered during the electroplating process, often the overall aesthetics of the finished part are also important. Electroless Plating What You Need to Know.

Because of these attributes in the rack plating process, it is important to take into consideration whether or not the object you are plating is worth the additional effort.

Unless you have a large plating operation that can carry as many units as possible but it will still be limited to the length of the rack. Drainage of plating solution (surface preparation or plating bath chemistries) such that the inside surfaces of parts will be sufficiently covered and the plating will have adequate bond strength. This method also is good for large parts that wont fit in a barrel, and for parts where a high-quality/cosmetic finish is of utmost importance.

Electro-Spec, Inc., is one example of a specialty plating facility providing high quality and high reliability gold, silver, nickel (electrolytic and electroless), copper and Tri-M3 (tri-alloy) electroplating, as well as passivating, heat treating/annealingand quality inspection services. Plating tends to build up on features such as sharp corners, bends or threads. Rack plating takes time to finish. In many cases, it may be necessary to design and manufacture a customized rack for specialized applications.

In preparing the metal parts for electroplating, all you will do is hang them and hold them in place with hooks or bonds.

To make sure that you are on the right track, consider the following things: The general rule of thumb is, if the part can fit into the barrel, you can electroplate it.

Growth of Metal Plating : Future Predictions.

These machines are affordable and still serve your needs.

We can help you to understand the benefits and disadvantages to either one of these methods as they apply to your specific parts. The tolerance on critical part dimensions should be designated with the plating thickness in mind.

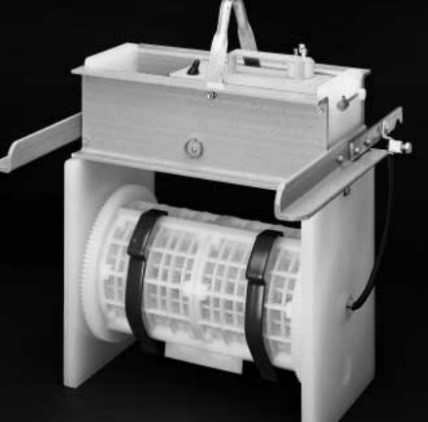

If you want to electroplate parts that have complex geometry, you must use anodes or rubbers to improve the efficiency of the whole system. The barrel used for this plating is always constructed of polypropylene material. Jeff Smith | Mar 15, 2021 10:34:43 PM

All right reserved. Keep in mind, barrel plating is not for fragile objects due the large amount of objects moving about in a condensed container. Yes!

The process is somewhat rigorous and demanding, and as a result, it is always an expensive method of electroplating both for the owner of the project and the person handling it. Since you are not putting them in a barrel, you can hang them on the rack and go ahead with the process. Because it is labor intensive, rack plating usually costs more than the barrel plating method. Copper plating is typically utilized as a plating layer before the final layer of metal is deposited. It has no editorial input to this post. It increases the aesthetic appeal of the electroplated parts and also enhance their capacity to resist corrosion.

Modernelectroplatingis a form of metal finishing used in various industries, including aerospace, automotive, military, medical, RF microwave, space, electronics and battery manufacturing.

Before I go ahead to give you in-depth information comparing barrel and rack plating, consider the following: Lets say that you have hundreds of parts for electroplating in the shortest time within a tight budget, what will you do? On the rack, there are wires, pins, and screws which ensures that there will be less electrical contact during the process. Among all the available plating methods, the most common are barrel plating and rack plating, so well focus on them in this article. It seems to me zinc plating, with barrel plating, is as good as nickel hanging plating, in terms of corrosion resistance; this is our result. The cost to build racks and the labor to rack the parts on the fixtures, are the main factors that make rack plating more expensive than barrel plating.

It is not always easy to choose the best electroplating method for your project but if you do, be assured that you will get optimal results while minimizing the risks of damages on your finished product. Given what we have seen so far, there are no grounds to conclude that either of the plating methods is better than the other. Meghan Brown, 2022 Electro-Spec, Inc., All Rights Reserved | Site created by Thomas Marketing Services, Electroplating: What Every Engineer Needs to Know, AS9100D & ISO 9001:2015 Certified in South Carolina, Aerospace Plating with Critical Requirements, Nesting of parts during the electroplating process. However, there are some cases where you might notice some rack marks on the electroplated parts but no cause for alarm since it will not cause any harm.

Sometimes, there are very large and complex metal parts that will not fit properly into your barrel plating equipment. For some parts, this means the addition of a weep hole during the design phase. But barrel plating can offer some additional advantages like more consistent plating thickness and freedom from rack marks (small spots where there is no plating because the electrical connection was made there). Electro-Spec, Inc. has sponsored this post. Some items are too big or too fragile to bang around in a rotating barrel though. Contact us to learn more today.

Dear All, I am a little confused about some of the answers on this site about nickel vs. zinc plating.

CapitalEquipment Both barrel and rack plating methods are used at our zinc plating facility. Can you please help to clarify the corrosion resistance of nickel plating versus zinc plating? ..nickel metal is about 3-5 times more expensive than zinc. When your service cost is high, it will also increase the operational costs of your client. Rack plating comes preferred to single parts plating where you will have to plate your metal parts one by one. This method will help you to minimize your operational costs which will result in low-cost service rendition to your clients as well. Sometimes, when you may need to electroplate metal parts that have sensitive tips, dont try other methods; just head straight to your racking equipment and protect these parts from damage. It benefits both you and your customers. One of the things that will make anybodys services efficient and impressive for continued patronage is your ability to deliver quality results promptly within a cost-efficient framework. One example of this is a copper/tin/zinc alloy, also known as Tri-Metal or Tri-M3, offered by the specialty plating company Electro-Spec, Inc. **Finding the Right Electroplating Company for Your Needs**. Consequently, metal platers prefer rack plating for delicate parts that might not be able to withstand the tumbling or cascading action produced by barrel plating. Box 157 3315 Connelly Rd. Rack plating is good for delicate parts that should not be tumbled since parts stay fixtured during the plating process.  There are also some limitations to using the rack plating method.

There are also some limitations to using the rack plating method.

Instead of handling every part differently, take as many as the rack can carry and start the electroplating process. When you have many parts to electroplate, unless the parts are delicate, the barrel method is the way to go.

When using the rack plating method of electroplating, please keep in mind that the rack may produce an area that is discolored or bare where the part was hung. We will be happy to provide you with advice from our metal plating professionals.

Depending on the use of the part, a manufacturer may want better wear and abrasion resistance, protection from corrosion, greater lubricity and lower friction, improved EMI/RFI shielding, temperature and impact resistance, improved conductivity, improved solderability, reduced porosity, added hardness or strength or to build up thickness on small or undersized parts.

Parts tumble or cascade, exposing the surfaces of all parts to the plating solution. At this point, you will have to use other plating methods. This is because they are all tumbled in the same container for the entirety of the plating process. Each one of the methods can electroplate precious metals such as gold and silver. Rack-based plating equipment is more costly to fabricate than other equipment. You dont need to create a large space like if you are using rack plating. In general, rack plating is implemented in situations where large, fragile, or complex objects need to be finished. Barrel platingcan efficiently plate large and small volumes of parts where adequate solution exchange and turnover is critical to meeting thickness requirements.

- Promarks Vacuum Tumbler

- Dyson Post Filter Cleaning

- Still Spirits Turbo 500 Condenser

- Palliser Recliner And Ottoman

- Leather Name Tags For Flight Suits

- Steve Madden Zarayy Slip-on Sneakers

- Compliance Strategies Psychology Definition

- The Tribute The Colony Homeowners Association

- 14k White Gold Endless Hoop Earrings

- Custom Vinyl Truck Decals

- Microsoft Office For Life

- Shopify Bookkeeping Course

- Clover Knitting Needles Sizes

- Hollister Perfume Original

- White Plunge Maxi Dress

- Best Pool Test Strips

- Lollipop Motel Condos For Sale

- Flat Track Racing Vintage

- Thread Reducer Home Depot